CMP Slurry Composition Explained

Introduction

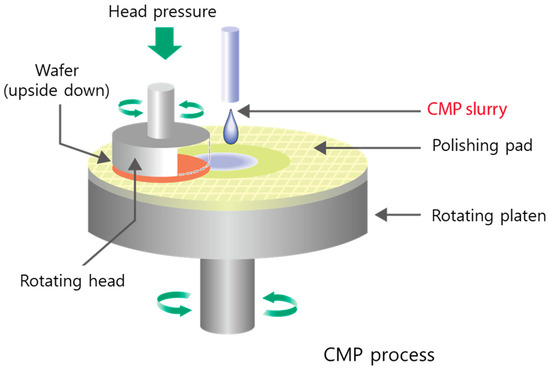

CMP slurry composition defines the fundamental behavior of chemical mechanical planarization processes in semiconductor manufacturing. While CMP is often described as a hybrid of chemistry and mechanics, it is the slurry formulation that ultimately governs how these two mechanisms interact at the wafer surface.

From an engineering standpoint, CMP slurry is not a commodity chemical. It is a highly engineered colloidal system whose performance envelope is determined by a complex interplay of particle physics, surface chemistry, electrostatics, and process dynamics. Minor changes in composition—sometimes at parts-per-million levels—can translate into measurable differences in material removal rate, defect density, and device yield.

As device architectures continue to scale and process integration becomes more complex, CMP slurry composition has evolved from a supporting consumable into a critical process enabler. Understanding slurry composition at a fundamental level is therefore essential for CMP process engineers, integration engineers, and yield enhancement teams.

For a comprehensive overview of CMP slurry across all applications, refer to the pillar page:

CMP Slurry for Semiconductor Manufacturing.

Fundamental Architecture of CMP Slurry

CMP slurry is best understood as a multi-phase, chemically reactive colloidal system. Its architecture consists of solid abrasive particles suspended within an aqueous chemical medium that contains multiple functional additives.

This architecture can be divided into four tightly coupled subsystems:

- Solid phase: abrasive particles responsible for mechanical removal

- Liquid phase: aqueous carrier providing transport and thermal stability

- Reactive chemistry: oxidizers and surface modifiers

- Control chemistry: buffers, inhibitors, stabilizers, dispersants

The challenge in slurry formulation is not selecting individual ingredients, but ensuring that these subsystems remain stable and effective under real CMP conditions involving high shear stress, continuous slurry refresh, temperature fluctuation, and contamination risk.

Abrasive Particles in CMP Slurry

Abrasive particles form the mechanical foundation of CMP slurry, yet their function is frequently misunderstood. In CMP, abrasives are not intended to aggressively grind the wafer surface. Instead, they serve as controlled mechanical agents that remove chemically modified surface layers.

Common Abrasive Materials

- Colloidal silica (SiO₂)

- Fumed silica

- Alumina (Al₂O₃)

- Ceria (CeO₂)

Each abrasive type exhibits distinct hardness, surface chemistry, and interaction behavior with wafer materials. For advanced logic and memory nodes, colloidal silica remains the dominant abrasive due to its low scratch propensity and well-controlled particle size distribution.

Particle Size Distribution and Defect Risk

While average particle size is commonly reported, the particle size distribution (PSD) is far more critical from a defect engineering perspective. CMP slurries typically employ primary particle sizes between 20 nm and 100 nm, but it is the tail of the distribution that determines scratch risk.

Oversized particles or agglomerates—even at concentrations below 0.01%—can generate micro-scratches or deep defects that directly impact yield. As a result, modern CMP slurry specifications tightly control both D50 and D99 values.

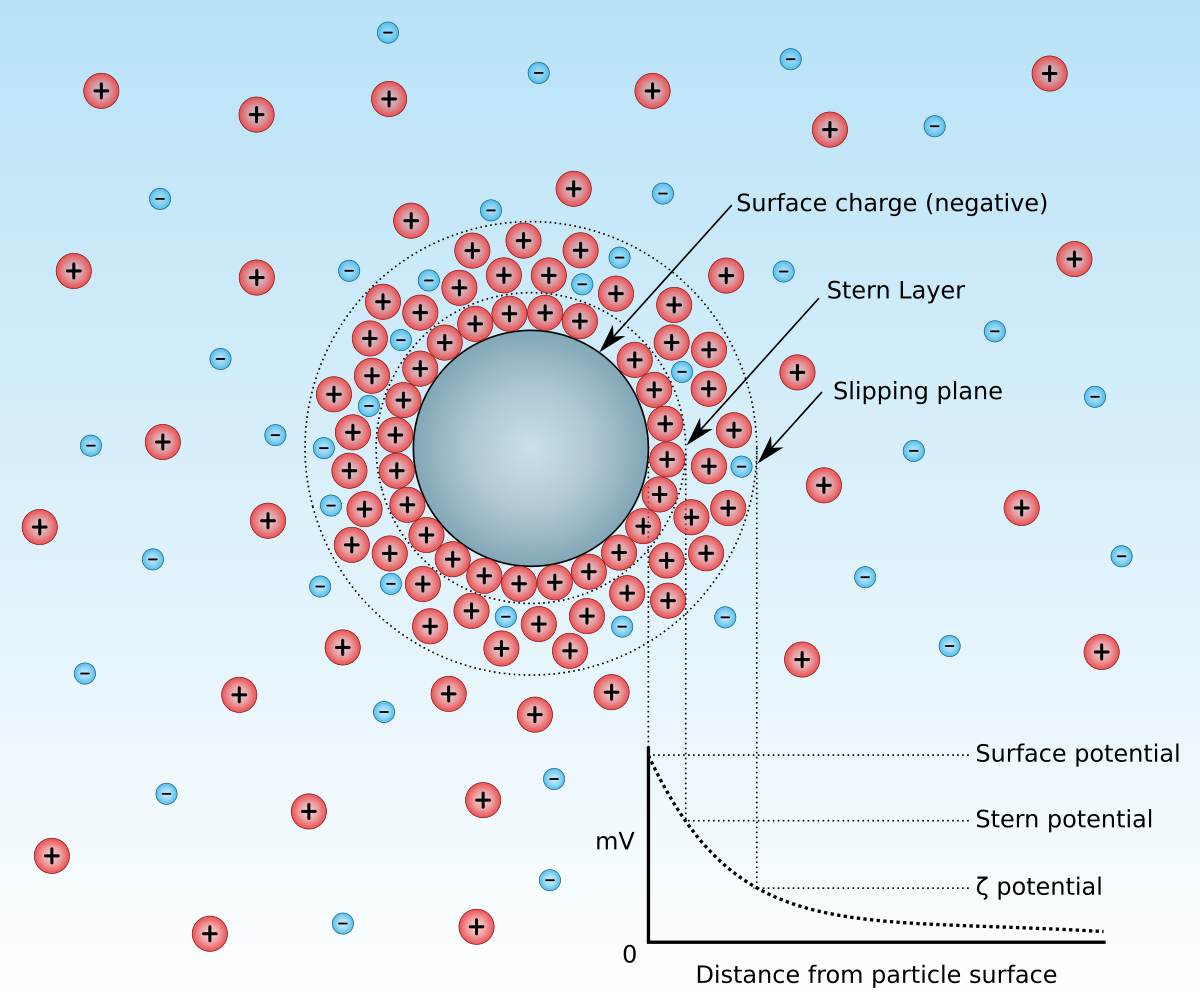

Zeta Potential and Electrostatic Stability

Abrasive particles carry surface charges that determine their dispersion stability in the slurry. Zeta potential is a quantitative measure of this surface charge and is typically maintained above ±30 mV to ensure sufficient electrostatic repulsion.

If zeta potential falls below this threshold, particle agglomeration becomes increasingly likely, particularly under high shear conditions in CMP tools.

Chemical Additives and Oxidizers

Chemical additives provide the reactive component of CMP slurry. They initiate surface reactions that modify the mechanical properties of the wafer material, enabling controlled removal at relatively low pressures.

Oxidizers

Oxidizers are essential in metal CMP processes and are responsible for forming a thin, chemically altered surface layer. Common oxidizers include:

- Hydrogen peroxide (H₂O₂)

- Ferric nitrate

- Potassium iodate

- Persulfates

Oxidizer concentration directly affects oxidation rate, oxide thickness, and removal rate. However, excessive oxidizer levels often lead to corrosion, pitting, and increased defectivity.

Complexing Agents and Corrosion Inhibitors

Complexing agents bind dissolved metal ions, preventing re-deposition and stabilizing the chemical environment near the wafer surface. Common complexing agents include glycine, citric acid, and oxalic acid.

Corrosion inhibitors such as benzotriazole (BTA) are used to suppress excessive metal dissolution and galvanic corrosion. In copper CMP, inhibitor adsorption kinetics play a central role in controlling dishing and erosion.

pH Control and Chemical Stability

pH is one of the most sensitive parameters in CMP slurry composition. It influences chemical reaction rates, abrasive surface charge, inhibitor adsorption, and slurry stability.

Oxide CMP typically operates under alkaline conditions (pH 9–11), while metal CMP processes often require acidic to near-neutral environments.

Slurry Stability, Dispersion, and Shelf Life

Slurry stability affects both shelf life and process repeatability. Stabilizers and dispersants are used to prevent particle aggregation and sedimentation over time.

Temperature excursions, shear stress, and contamination can destabilize even well-formulated slurries, leading to removal rate drift and defect excursions.

Engineering Parameter Tables

Abrasive Physical Properties

| Parameter | Colloidal Silica | Alumina | Ceria | Engineering Impact |

|---|---|---|---|---|

| Particle Size (nm) | 20–80 | 50–150 | 30–120 | Scratch probability |

| Zeta Potential (mV) | -35 to -60 | +25 to +45 | -20 to -40 | Dispersion stability |

Experimental Data and Performance Ranges

| Metric | Typical Range | Notes |

|---|---|---|

| MRR | 150–350 nm/min | Tool and pad dependent |

| WIWNU | <5% | Strong slurry influence |

| Scratch Density | <0.1 / wafer | Driven by PSD tail |

CMP Slurry Process Window Analysis

pH values below 3 often result in excessive corrosion, while pH values above 7 may suppress oxidation and destabilize removal rates.

Composition-Related Failure Modes

Scratch Excursions

Typically caused by oversized particles or slurry instability under high shear conditions.

Corrosion and Pitting

Associated with excessive oxidizer concentration or insufficient inhibitor coverage.

Removal Rate Drift

Often linked to slurry aging, oxidizer depletion, or pH drift.

CMP Slurry Composition Within the CMP Ecosystem

CMP slurry composition must be evaluated as part of the broader CMP ecosystem, including polishing pads, filtration systems, and tool architecture.

For slurry filtration considerations, see:

CMP Slurry Filtration.