CMP Slurry Types Explained

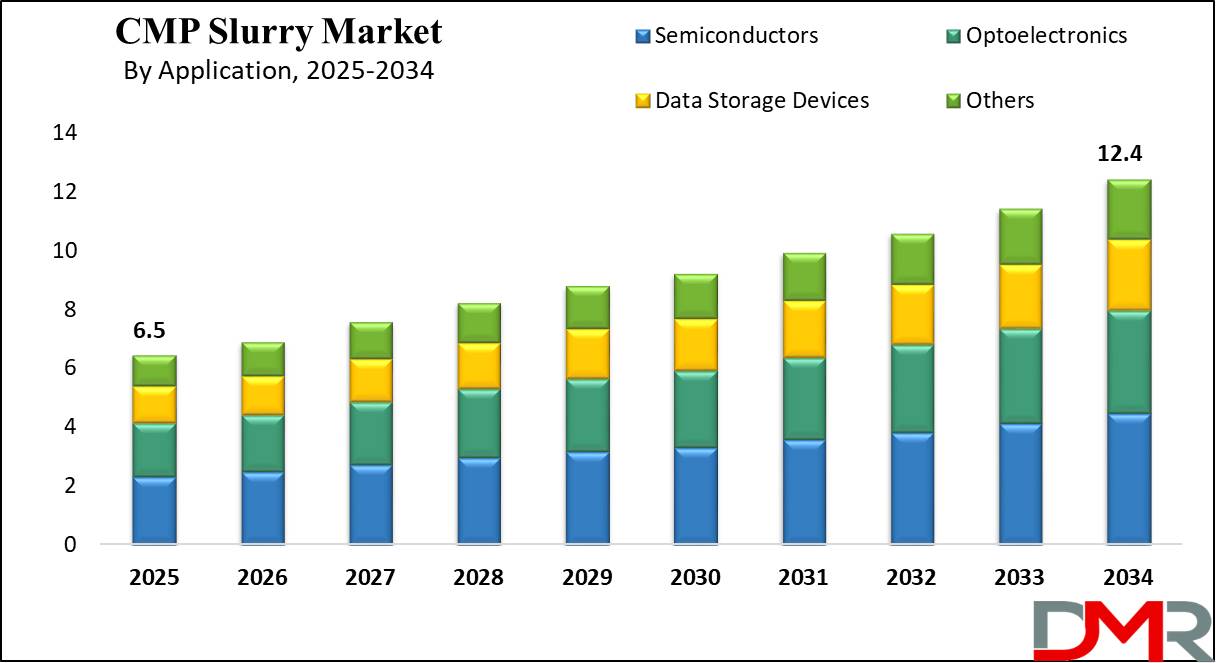

Introduction: Why CMP Slurry Types Matter

CMP slurry types are often oversimplified in commercial literature, frequently reduced to labels such as “oxide slurry” or “copper slurry.” In real semiconductor manufacturing environments, however, slurry type selection directly defines removal mechanisms, defect modes, integration risk, and ultimately yield.

As technology nodes shrink and device architectures become increasingly heterogeneous, a single “generic” slurry can no longer satisfy multiple process requirements. Modern CMP relies on highly specialized slurry types, each optimized for a narrow operating window.

This document provides a white-paper level classification of CMP slurry types, grounded in material science, surface chemistry, and high-volume manufacturing (HVM) experience.

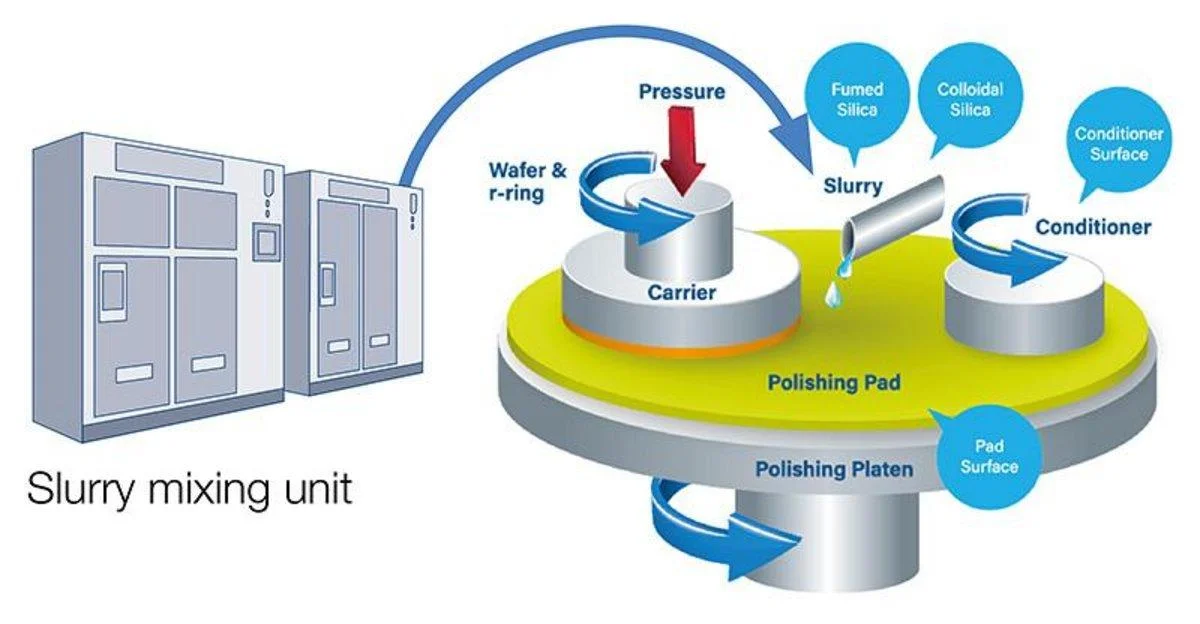

For a holistic overview of CMP slurry fundamentals, refer to:

CMP Slurry for Semiconductor Manufacturing

CMP Slurry Classification Logic

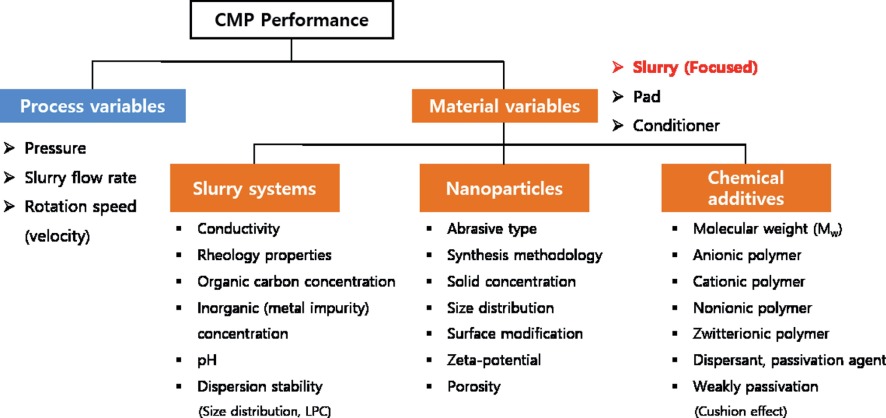

CMP slurry types can be classified using multiple orthogonal dimensions. Relying on a single classification axis often leads to incorrect slurry selection.

Primary Classification Dimensions

- Target material (oxide, metal, barrier, dielectric)

- Chemical mechanism (oxidation-driven, dissolution-driven)

- Abrasive system (silica, alumina, ceria, hybrid)

- Technology node (legacy vs advanced nodes)

- Integration sensitivity (low-k compatibility, corrosion risk)

Oxide CMP Slurry

Application Scope

Oxide CMP slurry is primarily used for interlayer dielectric (ILD) planarization, shallow trench isolation (STI), and pre-metal dielectric steps.

Typical Composition Architecture

- Abrasive: Colloidal silica

- pH: Alkaline (9.5–11.5)

- Additives: Buffers, dispersants, trace inhibitors

Engineering Parameter Table

| Parameter | Typical Range | Impact |

|---|---|---|

| Particle Size (D50) | 30–70 nm | Scratch vs MRR balance |

| MRR | 200–500 nm/min | Throughput |

| WIWNU | <4% | Planarity control |

Process Window Illustration

Copper CMP Slurry

Copper CMP slurry is among the most chemically complex slurry types due to copper’s high chemical reactivity and susceptibility to corrosion.

Two-Step Copper CMP Slurry System

- Bulk Cu slurry: High MRR, controlled oxidation

- Cu barrier / buff slurry: Low MRR, high selectivity

Key Chemical Components

- Oxidizer: H2O2 (1–5 wt%)

- Complexing agent: Glycine, citric acid

- Inhibitor: Benzotriazole (BTA)

| Metric | Bulk Cu | Cu Buff |

|---|---|---|

| MRR | 300–800 nm/min | 50–150 nm/min |

| Dishing | <40 nm | <15 nm |

Tungsten CMP Slurry

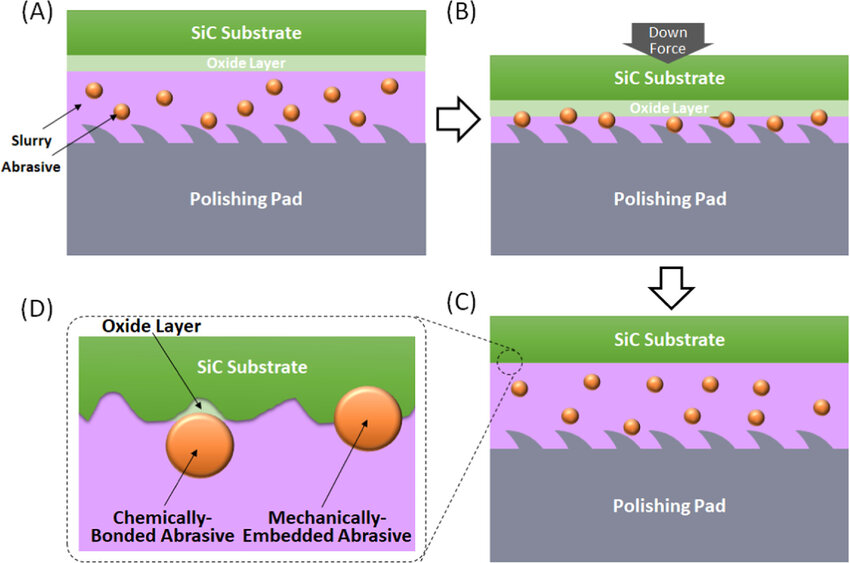

Tungsten CMP slurry relies heavily on chemical dissolution mechanisms rather than pure mechanical abrasion.

- pH: Acidic (2–4)

- Oxidizer: Ferric nitrate

- Abrasive: Fine silica or alumina

| Parameter | Range |

|---|---|

| MRR | 150–400 nm/min |

| Oxide Selectivity | >30:1 |

Barrier & Hard Mask CMP Slurry

Barrier CMP slurries target materials such as Ta, TaN, TiN, and advanced hard masks.

These slurries prioritize selectivity over absolute removal rate.

| Material | Preferred Abrasive | Risk |

|---|---|---|

| Ta/TaN | Alumina | Micro-scratch |

| TiN | Hybrid | Erosion |

Low-k & Advanced Dielectric Slurry

Low-k CMP slurry types are among the most integration-sensitive formulations due to mechanical fragility and chemical sensitivity of porous dielectrics.

- Ultra-low abrasive loading

- Neutral pH systems

- Strict scratch density control

Node-Driven Slurry Types

Slurry types evolve with technology nodes. Advanced nodes demand tighter control over defectivity, selectivity, and process window width.

Slurry Type vs Process Window

Each slurry type defines a unique operating window determined by pH, oxidizer concentration, abrasive loading, and pad interaction.

Slurry Selection Decision Matrix

| Application | Recommended Slurry Type | Key Constraint |

|---|---|---|

| STI | Oxide slurry | Scratch density |

| Cu BEOL | Copper slurry | Dishing control |

Type-Specific Failure Modes

Oxide Slurry

Micro-scratches from PSD tail

Copper Slurry

Corrosion, galvanic pitting

Barrier Slurry

Selectivity loss, erosion