Semiconductor silicon wafer polishing liquid

Silicon wafer polishing liquid / Silicon wafer polishing and grinding / Semiconductor wafer grinding and polishing

Jizhi Electronics · Silicon Wafer Polishing Liquid · Semiconductor Wafer CMP Polishing Liquid · Si Slurry

Key Features

- For 8-12″ Wafer large silicon wafers

- The rough polishing, medium polishing and fine polishing of recycled wafers by CMP

- The assembly process requirements for high-quality semiconductor wafers

Product Name

Silicon wafer polishing liquid / Silicon wafer polishing and grinding / Semiconductor wafer grinding and polishing

Silicon Wafer Polishing Slurry Functions:

It is used for coarse polishing, medium polishing and fine polishing of 8-12″ Wafer large silicon wafers and recycled wafers, reducing the unevenness on the wafer surface. It meets the assembly process requirements of high-quality semiconductor wafers.

Product Features

- High removal rate and stable removal rate.

- Good circulation, high dilution ratio, and low surface roughness.

- The fine polishing liquid features low particle residue, low surface roughness, low haze value and low metal ion content.

| Slurry type | Benchmark products | Product advantages |

|---|---|---|

| Silicon wafer rough polishing liquid | Fujimi 6103 Cabot 2600 Ace nano WP5000 NP7050 | This coarse polishing process, suitable for 8-12 inch wafers and recycled silicon wafers, features a high removal rate (0.8-1.0 um/min), good circulation, high dilution ratio, and low surface roughness (Ra < 0.7 nm, 30 um x 30 um, AFM). It is used at a dilution ratio of 1:20 to 1:40. |

| Polishing liquid for silicon wafers | Fujimi1306 Cabot SFP200X | The two-step coarse polishing solution for 8-12-inch wafers and recycled silicon wafers features a high removal rate (0.2-0.6 um/min), good cycle performance, and a high dilution ratio. It achieves a low surface roughness (Ra < 0.3 nm, 30 um x 30 um, AFM) and is used at a dilution ratio of 1:20 to 1:40. |

| Silicon wafer fine polishing liquid | Fujimi3108 NP 8040 Cabot 330C | Final-stage precision polishing solution for 8-12-inch large silicon wafers and recycled wafers, featuring low particle residue (12-inch wafer, 55nm PA < 80ea, SP5), low surface roughness (12-inch wafer, Ra < 0.10nm, 30um x 30um, AFM), low haze value (12-inch wafer, Haze ≤ 0.08, SP5), and low metal ion content (Mn+ total < 5ppm, ICP-MS). Dilute 1:19 before use. |

The surface of semiconductor wafers is ground and polished using JZ Electronic CMP polishing equipment and grinding/polishing fluids to reduce the surface roughness of silicon wafers, wafers and other workpieces, and to obtain a bright and flat surface.

Jizhi Electronics’ Si Slurry is suitable for polishing large silicon wafers and recycled wafers, achieving excellent surface flatness, fast polishing rate, high yield, and uniform surface without defects.

Rough-Polishing Slurry for Silicon Wafers

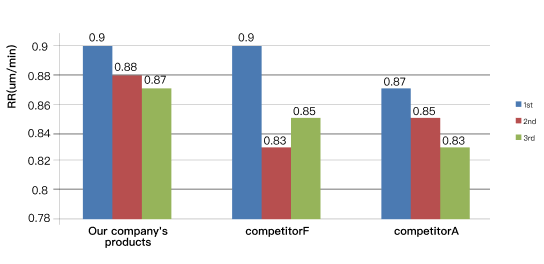

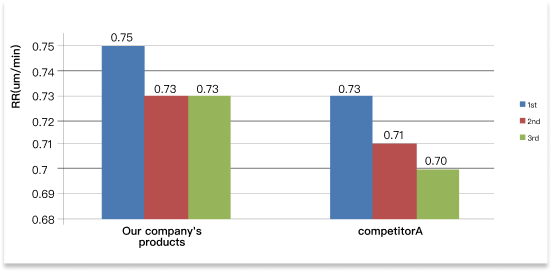

(Comparison with Japanese and Korean Companies under High Pressure and High Rotation Conditions)

Rough-Polishing Slurry for Silicon Wafers (Comparison with Japanese and Korean Companies under High Pressure and High Rotation Conditions)

| Test Equipment | SPEEDFAM 36B (4 Pressure Heads) |

|---|---|

| Polishing Pad Model | SUBA 800 |

| Test Wafer | Silicon Wafer (P-Type) |

| Polishing Temperature | 35 °C |

| Platen Rotation Speed | 80 rpm |

| Pressure | 0.35 kg/cm² |

| Slurry Circulation Rate | 10 L/min |

| Dilution Ratio | 20× Dilution |

| Polishing Pad Model | SUBA 800 |

| Test Wafer | Silicon Wafer (P-Type) |

| Polishing Temperature | 39 °C |

| Platen Rotation Speed | 40 rpm |

| Pressure | 0.25 kg/cm² |

| Slurry Circulation Rate | 10 L/min |

| Dilution Ratio | 20× Dilution |

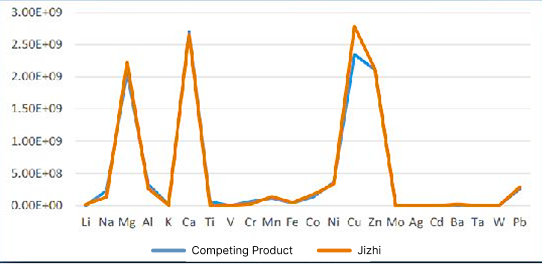

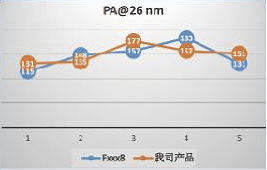

Comparison of Metal Ion Content on Wafer Surfaces Between Our Product and Competitors

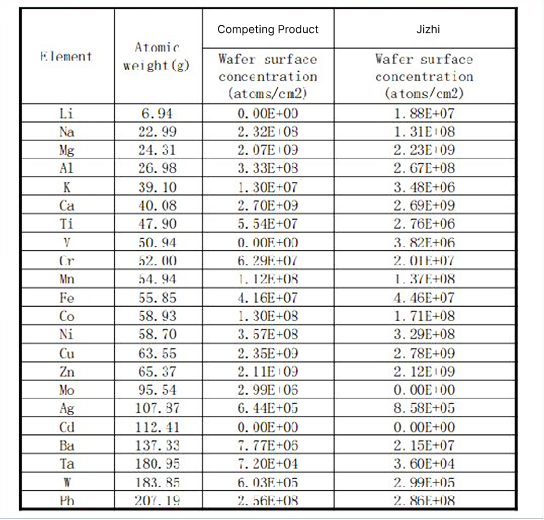

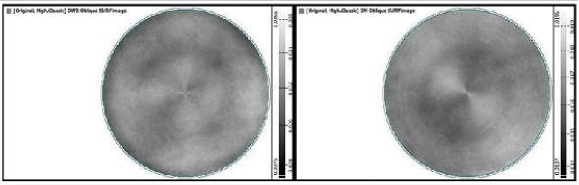

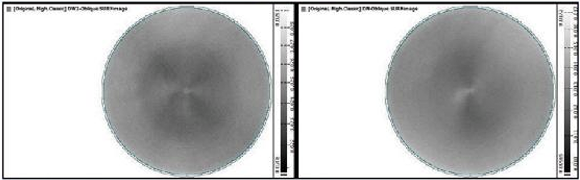

SP 555 nm test maps show that the surfaces of wafers processed with Competitor F and with our product exhibit few defects, no abnormal surface morphology, and no scratches.

| Test Equipment | 300T |

|---|---|

| Test Wafer | Reclaimed Wafer |

| Inspection Equipment | SP5 |

| Cleaning Conditions | MEG+SC1+DHF+SRD |

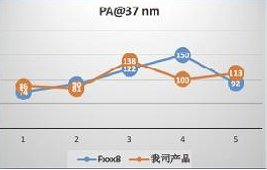

In terms of particle performance, compared with competing products, our polishing slurry offers 37 nm and 26 nm particle removal capability comparable to that of Competitor F.

Comparison of Metal Ion Content on Wafer Surfaces Between Our Product and Competitors

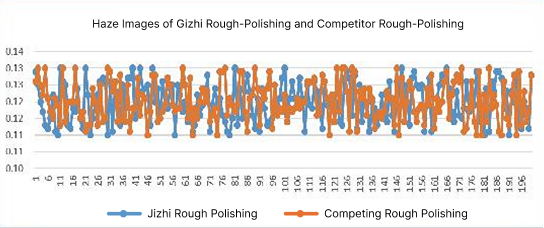

The haze of our product is approximately 0.03,

while that of Competitor F is approximately 0.04.

Competitor F

Our company’s products

Competitor F

Our company’s products

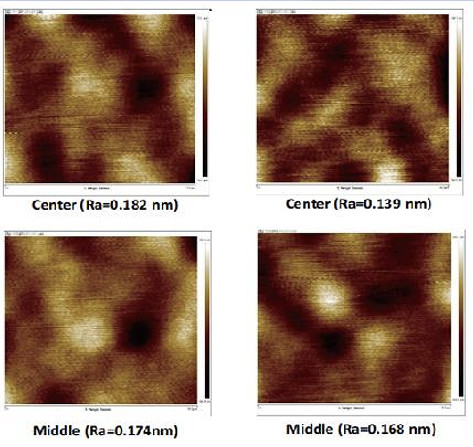

Roughness Performance Comparison

| AFM roughness | Foreign Competitor | Our Product | |

|---|---|---|---|

| Center | Ra(nm) | 0.182 | 0.139 |

| Middle | Ra(nm) | 0.174 | 0.168 |

| Mean Value | Ra(nm) | 0.178 | 0.153 |

Storage Method for Gizhi Electronics Semiconductor Silicon Wafer Polishing Slurry:

Store in a well-ventilated, cool, and dry warehouse. The product must be stored at 5–35 °C, protected from direct sunlight and from freezing. If stored below 0 °C, irreversible agglomeration may occur, rendering the product unusable.

Why choose Jizhi Electronics?

10 years of experience in optical material CMP

10 years of experience in optical material CMP

Polishing solutions and formulas are flexibly customized

Non-toxic, biodegradable formula meeting internati

Free process debugging

40% faster processing time compared to conventiona

Introduce foreign production technologies and equipment

Optimized consumption rate reduces overall operati