Silicon Carbide Substrate Grinding and Polishing

JIZHI Electronics · Silicon Carbide Grinding and Polishing · Semiconductor Wafer Polishing

Silicon Carbide Grinding Slurry / Silicon Carbide Polishing Slurry / Silicon Carbide (SiC) Lapping Pad / SiC Final Polishing Pad

Key Features

- Domestic Alternatives to Politex and FUJIBO Polishing Pads

Product Name

JIZHI Electronics · Silicon Carbide Grinding and Polishing · Semiconductor Wafer Polishing

Product Features

JIZHI Electronics has developed a four-step SiC polishing process that combines different grades of grinding slurries, polishing slurries, and polishing pads (coarse grinding pad, fine grinding pad, rough polishing pad, and final polishing pad). This process improves the surface quality of silicon carbide substrates in grinding and polishing applications while significantly increasing the material removal rate.

Process and Applications

Suitable for SiC silicon carbide substrate DMP and CMP process flows, effectively improving efficiency and yield. The silicon carbide polishing slurries and polishing pads enable localized (domestic) replacement of imported products.

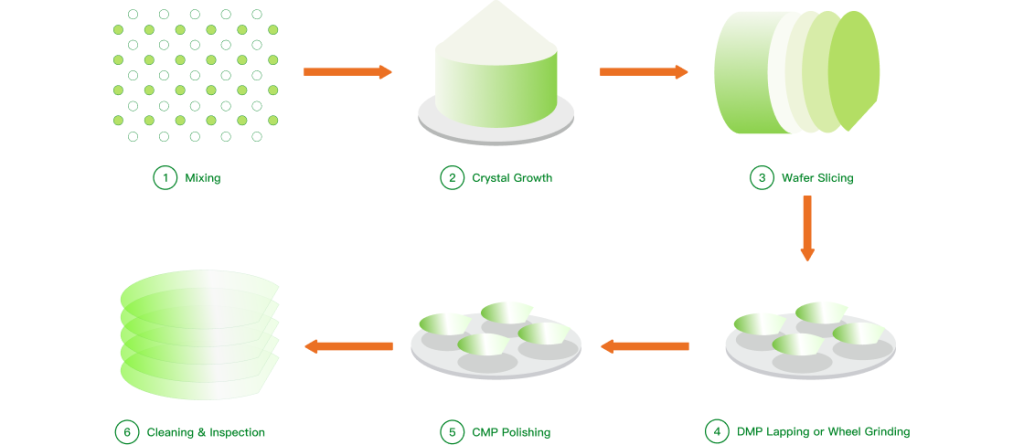

Brief Overview of the Silicon Carbide Substrate Processing Flow

Silicon Carbide (SiC) Grinding Process – Rough Grinding / Fine Grinding

Step1

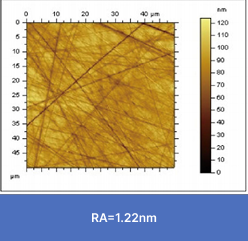

JIZHI Electronics Silicon Carbide (SiC) Rough Grinding Process

| SiC Double-Sided Rough Grinding Process | |

|---|---|

| Verification Equipment | 双面36B |

| Wafer | 6″SiC |

| Polishing Slurry | JZ-8003 |

| Polishing Pad | JZ-1020 |

| Pressure | 3 psi |

| Upper Platen Rotation Speed | 25 rpm |

| Lower Platen Rotation Speed | 10 rpm |

| Slurry Flow Rate | 5L /min |

| Polishing Rate | 25-30um/H |

| Surface Roughness | 1.22nm |

| TTV (Total Thickness Variation) | <2 |

| Warp | <30 |

| Bow | <10 |

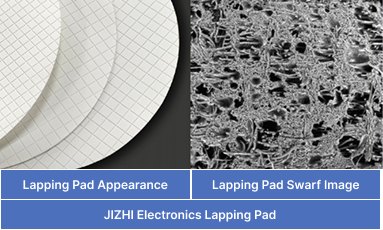

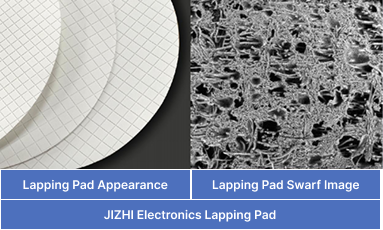

| Rough Grinding · Used with Lapping Pad | |

|---|---|

| Lapping Pad Dimensions and Specifications | |

| Model | JZ-1020 |

| Thickness | 1.4 mm |

| Groove Pattern | Customizable |

| Hardness | Shore A 85° |

| Compression Ratio | 2.92 |

Step2

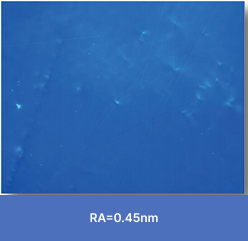

JIZHI Electronics Silicon Carbide (SiC) Fine Grinding Process

| SiC Double-Sided Rough Grinding Process | |

|---|---|

| Verification Equipment | 双面36B |

| Wafer | 6″SiC |

| Polishing Slurry | JZ-8001 |

| Polishing Pad | JZ-1020 |

| Pressure | 3 psi |

| Upper Platen Rotation Speed | 25 rpm |

| Lower Platen Rotation Speed | 10 rpm |

| Slurry Flow Rate | 5L /min |

| Polishing Rate | 6.8um/H |

| Surface Roughness | 0.45nm |

| TTV (Total Thickness Variation) | <2 |

| Warp | <30 |

| Bow | <20 |

| ine Grinding · Used with Lapping Pad | |

|---|---|

| Lapping Pad Dimensions and Specifications | |

| Model | JZ-1020 |

| Thickness | 1.4 mm |

| Groove Pattern | Customizable |

| Hardness | Shore A 85° |

| Compression Ratio | 2.92 |

JIZHI Electronics’ CMP rough and fine grinding process for SiC substrates

Tip 1 – Using rough grinding slurry with a lapping pad, Ra can reach 1.22 nm or lower.

Tip 2 – Using fine grinding slurry with a lapping pad, Ra can reach 0.45 nm or lower.

Silicon Carbide (SiC) Polishing Process – Rough Polishing / Fine Polishing

Step3

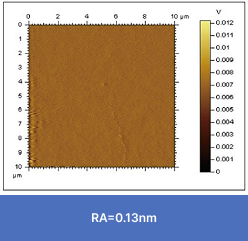

JIZHI Electronics Silicon Carbide (SiC) Rough Polishing Process

| SiC Substrate CMP Rough Polishing Process | |

|---|---|

| Verification Equipment | 双面36B |

| Wafer | 6″SiC |

| Polishing Slurry | JZ-8010 |

| Polishing Pad | JZ-3020 |

| Pressure | 350g/cm2 |

| Rotation Speed | 40 rpm |

| Polishing Rate | 2.5um/H |

| Surface Roughness | 0.13nm |

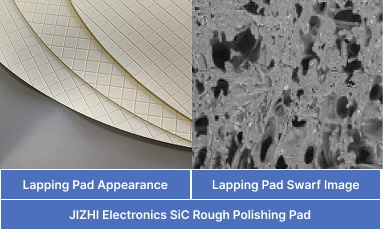

| Rough Polishing Pad Dimensions and Specifications | |

|---|---|

| Model | JZ-3020 |

| Thickness | 1.4 mm |

| Groove Pattern | Customizable |

| Hardness | Shore A 85° |

| Compression Ratio | 2.94 |

Step4

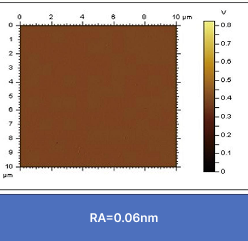

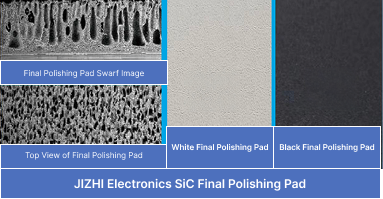

JIZHI Electronics Silicon Carbide (SiC) Final Polishing Process

| SiC Substrate CMP Rough Polishing Process | |

|---|---|

| Verification Equipment | 双面36B |

| Wafer | 6″SiC |

| Polishing Slurry | JZ-8020 |

| Polishing Pad | JZ-326 |

| Pressure | 300g/cm2 |

| Rotation Speed | 40 rpm |

| Polishing Rate | 0.25um/H |

| Surface Roughness | 0.06nm |

| Rough Polishing Pad Dimensions and Specifications | |

|---|---|

| Model | JZ-326 |

| Thickness | 1.3 mm |

| Groove Pattern | Customizable |

| Hardness | Shore A 51° |

| Compression Ratio | 10.77 |

JIZHI Electronics’ CMP rough and final polishing process for SiC substrates

Tip 3 – Using rough polishing slurry with a lapping pad, Ra can reach 0.13 nm or lower.

Tip 4 – Using final polishing slurry with a final polishing pad, Ra can reach 0.06 nm or lower.

Recommended Products and Parameters for Silicon Carbide Grinding / Polishing Processes

| Processing Method | Recommended Products | Removal Rate | Surface Quality | ||

|---|---|---|---|---|---|

| Polishing Slurry | Polishing Pad | ||||

| Final Polishing | Grinding / Lapping | JZ-8003 | JZ-1020 | 25-30um/H | 1.22nm |

| Final Polishing | JZ-8001 | JZ-1020 | 6.8um/H | 0.45nm | |

| Polishing | Rough Polishing | JZ-8010 | JZ-3020 | 2.5um/H | 0.13nm |

| Final Polishing | JZ-8020A JZ-8020B |

JZ-326 | 0.25um/H | 0.06nm | |

Storage Method for JIZHI Electronics SiC Silicon Carbide Polishing Slurry

Store in a well-ventilated, cool, and dry warehouse. The product must be stored at 5–35 °C, protected from direct sunlight and from freezing. If stored below 0 °C, irreversible agglomeration may occur, rendering the product unusable.

Pricing of JIZHI Electronics CMP / Slurry Polishing Liquids

JIZHI Electronics’ CMP metal polishing slurries are manufactured using advanced overseas production technologies and equipment and are formulated with specialized chemical compositions. The quality of JIZHI Electronics’ polishing slurries is comparable to that of similar imported products.

Thanks to localized production, JIZHI Electronics’ CMP slurries offer short delivery lead times, stable high quality, and competitive, cost-effective pricing.

Why choose Jizhi Electronics?

10 years of experience in optical material CMP

10 years of experience in optical material CMP

Polishing solutions and formulas are flexibly customized

Non-toxic, biodegradable formula meeting internati

Free process debugging

40% faster processing time compared to conventiona

Introduce foreign production technologies and equipment

Optimized consumption rate reduces overall operati