How to Choose CMP Slurry

An Engineering-Level Decision Framework for Semiconductor Wafer Polishing

1. Introduction

Choosing the right CMP slurry is one of the most consequential decisions in semiconductor manufacturing. Unlike many consumables, slurry selection directly impacts material removal rate (MRR), uniformity, defectivity, yield, and cost of ownership.

At advanced nodes, an improperly selected slurry can silently degrade yield long before catastrophic failure becomes visible.

This document provides a structured, engineering-driven methodology for selecting CMP slurry based on material science, process integration, and manufacturing realities.

For slurry fundamentals, refer to:

CMP Slurry for Semiconductor Manufacturing

2. First-Principles Approach to Slurry Selection

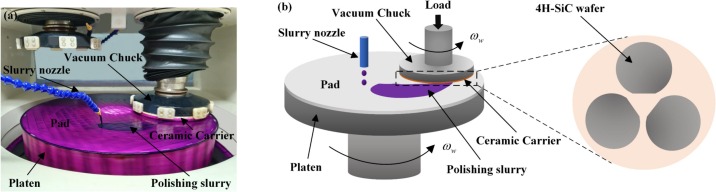

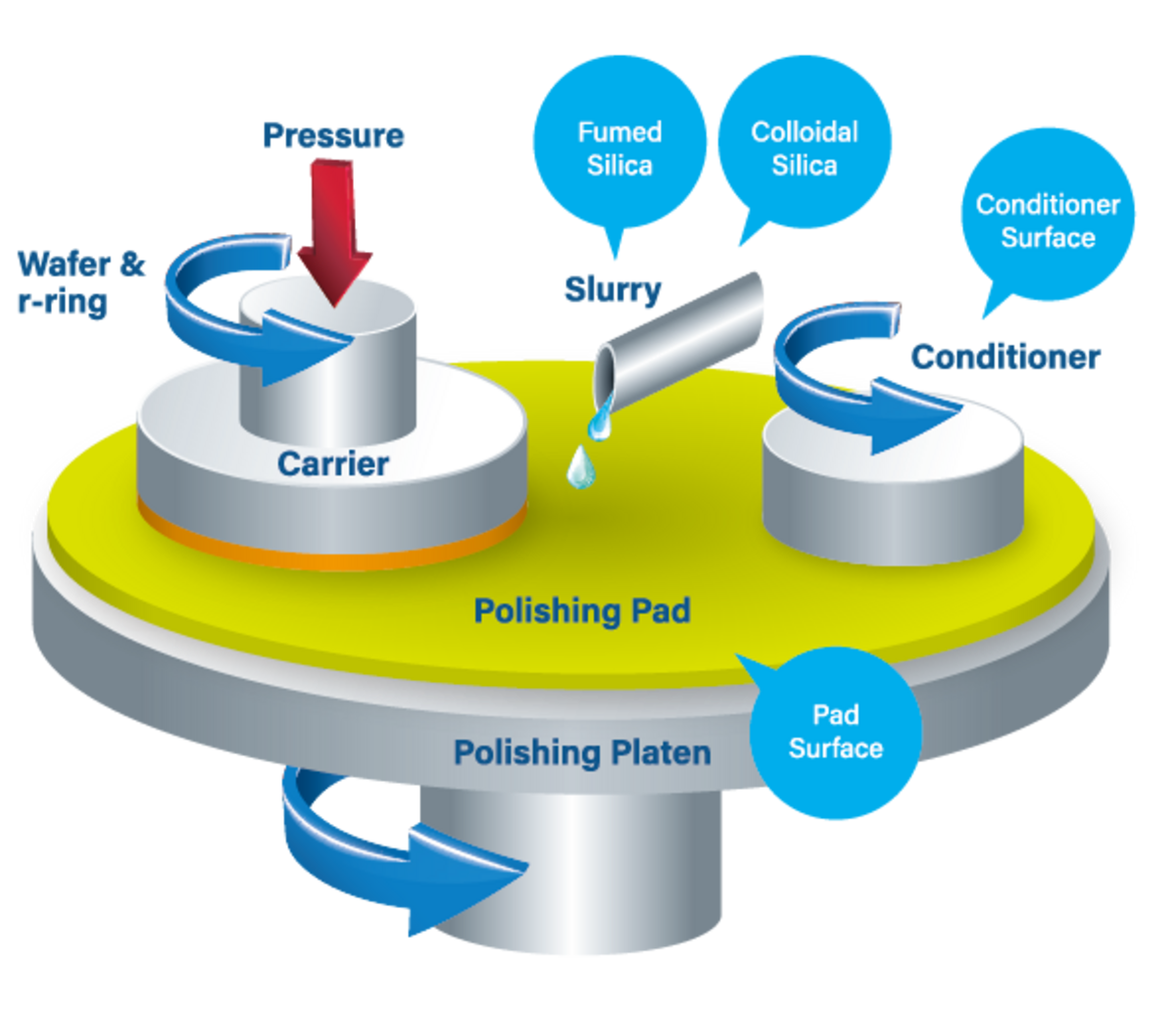

CMP is governed by a synergistic interaction of:

- Mechanical abrasion

- Chemical reaction

- Hydrodynamic transport

Slurry selection must therefore begin with first principles, not product catalogs.

3. Wafer Material Considerations

Different materials require fundamentally different slurry chemistries.

| Material | Key Challenge | Preferred Slurry Traits |

|---|---|---|

| SiO₂ | Uniform removal | Colloidal silica, alkaline pH |

| Copper | Dishing & corrosion | Controlled oxidation, inhibitors |

| Tungsten | Hardness | Strong oxidizers, alumina |

| Barrier Layers | Selectivity | Low MRR, high control |

Material selection logic must consider not only the top layer but also underlying and adjacent films.

4. Matching Slurry Type to CMP Process

Slurry type must match the CMP step objective.

- Bulk removal

- Clear step

- Barrier polish

Using a high-MRR slurry for a barrier step is a common but costly mistake.

For reference:

CMP Slurry Types

5. Key Performance Metrics

| Metric | Why It Matters | Typical Range |

|---|---|---|

| MRR | Throughput | 100–5000 Å/min |

| WIWNU | Uniformity | < 5% |

| Scratch Density | Yield | < 0.1/cm² |

| Selectivity | Profile control | > 5:1 |

6. Process Window & Margin Engineering

An optimal slurry is not the one with the highest peak performance, but the one with the widest stable process window.

Wider windows tolerate:

- Pad aging

- Tool-to-tool variation

- Minor chemistry drift

7. Compatibility with CMP Polishing Pads

Pad–slurry compatibility determines real-world performance.

| Pad Type | Slurry Compatibility | Risk |

|---|---|---|

| Hard polyurethane | High | Scratch risk |

| Soft porous pad | Moderate | Dishing |

Slurry selection without pad consideration is incomplete.

8. Defectivity & Yield Risk Assessment

Each slurry formulation has a characteristic defect fingerprint.

- Scratches → abrasive tail risk

- Pitting → oxidizer excess

- Dishing → inhibitor imbalance

Understanding this fingerprint allows proactive yield control.

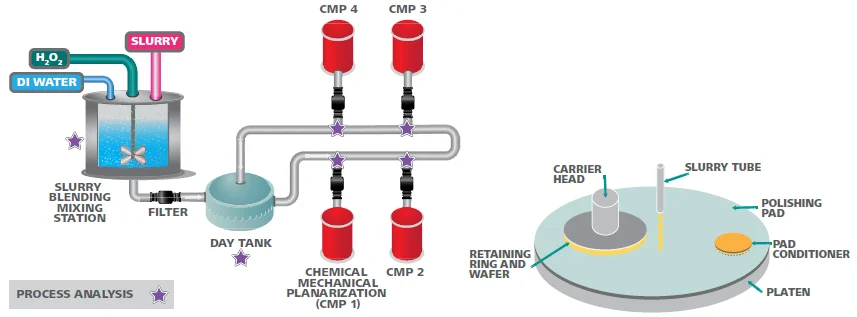

9. CMP Tool & Delivery System Constraints

Slurry must be compatible with:

- Flow rate limits

- Filter pore size

- Recirculation systems

For filtration considerations, see:

CMP Slurry Filtration

10. High-Volume Manufacturing (HVM) Considerations

HVM slurry selection prioritizes stability over peak performance.

| Factor | Engineering Focus |

|---|---|

| Batch consistency | Lot-to-lot control |

| Shelf life | Minimal aging drift |

| Supply reliability | Dual sourcing readiness |

11. Common CMP Slurry Selection Mistakes

- Chasing maximum MRR

- Ignoring filtration constraints

- Underestimating pad interactions

- Skipping long-term aging tests

Most yield excursions originate from these avoidable errors.

12. Qualification & Ramp-Up Strategy

A structured qualification plan includes:

- Lab-scale screening

- Short-loop tool tests

- Extended defect monitoring

- HVM pilot runs

13. Engineering Summary

Choosing CMP slurry is an engineering decision, not a purchasing choice. The optimal slurry balances performance, stability, defectivity, and manufacturability within a well-defined process window.

A disciplined selection methodology reduces yield risk, accelerates ramp-up, and lowers total cost of ownership.