Metal CMP Slurry for Semiconductor Wafer Polishing

1. Introduction to Metal CMP

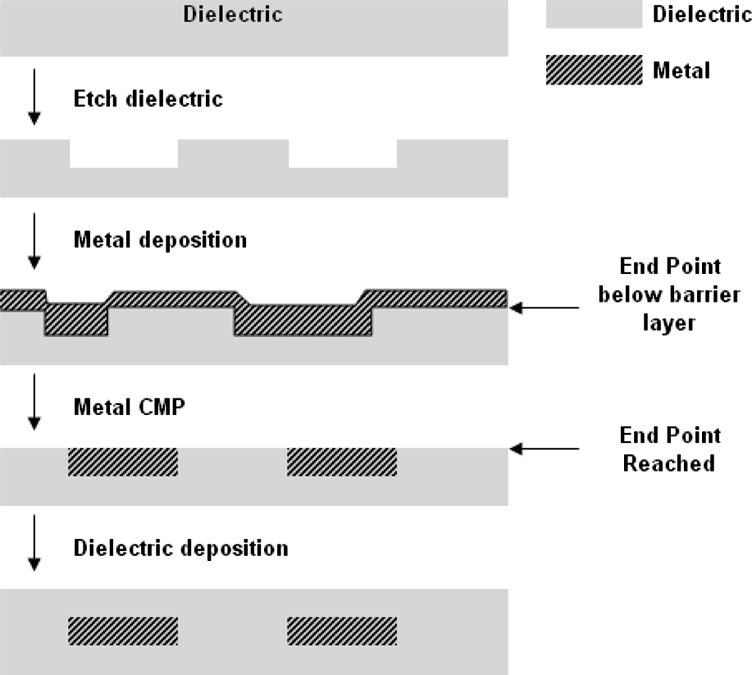

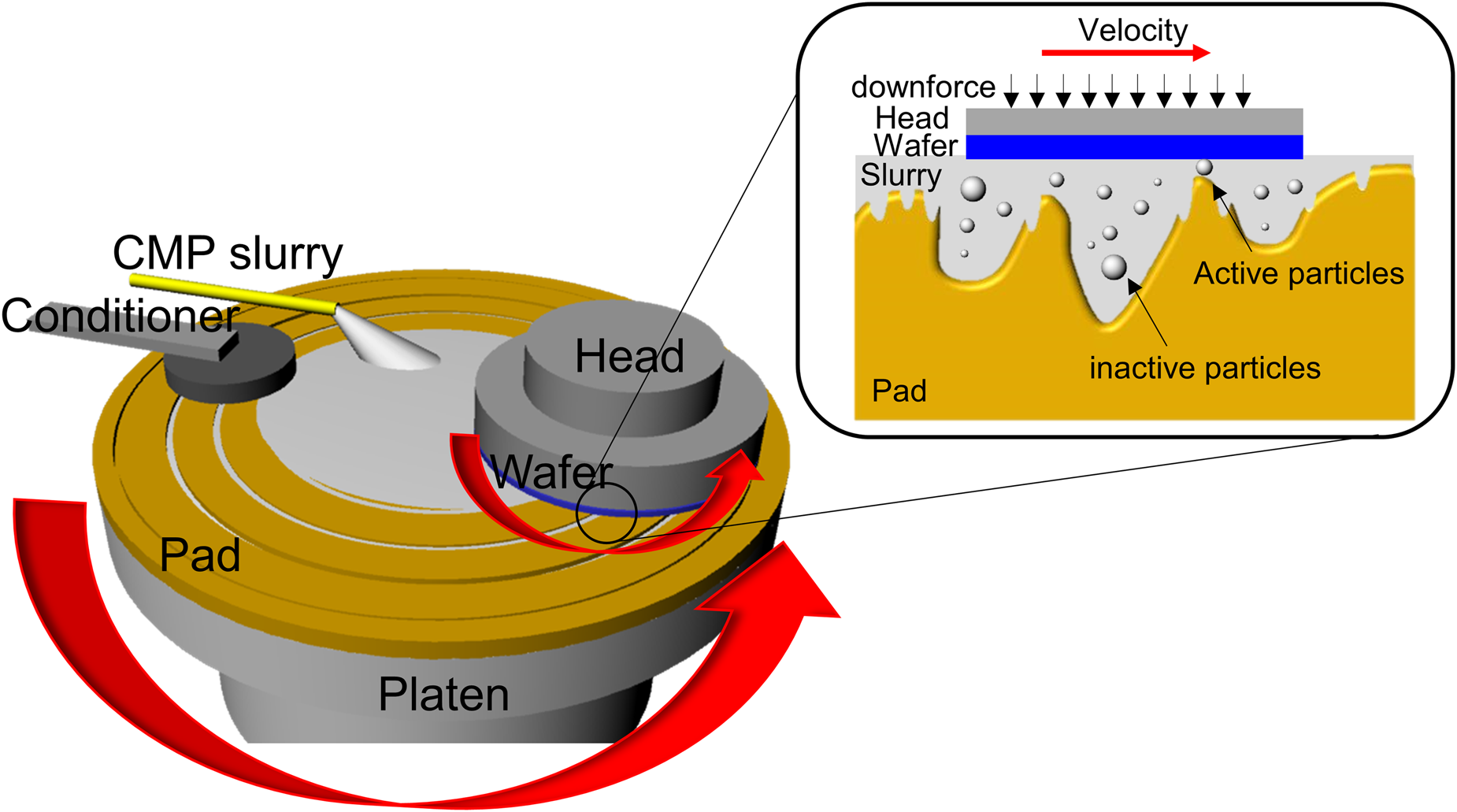

Metal Chemical Mechanical Planarization (CMP) is one of the most integration-critical processes in advanced semiconductor manufacturing. Unlike dielectric CMP, metal CMP involves electrochemically active materials whose surface states are highly sensitive to slurry chemistry, redox conditions, and mechanical interactions.

As device architectures evolve toward smaller geometries and heterogeneous material stacks, CMP slurries must simultaneously satisfy competing requirements of removal rate, selectivity, defect control, and corrosion suppression.

This white paper provides a unified engineering framework for understanding metal CMP slurry behavior across multiple metallic materials including copper, tungsten, aluminum, cobalt, and emerging ruthenium systems.

For a high-level overview of CMP slurry fundamentals, refer to:

CMP Slurry for Semiconductor Manufacturing

2. Why Metal CMP Is Fundamentally Different

Metal CMP differs fundamentally from oxide CMP due to the following factors:

- Metals exhibit electrochemical reactivity

- Surface passivation layers dynamically form and dissolve

- Removal rates are often chemistry-limited rather than mechanically limited

In metal CMP, slurry chemistry actively controls:

- Oxide formation kinetics

- Surface corrosion behavior

- Interfacial adhesion between metal and pad

3. Classification of Metal CMP Slurry Types

Metal CMP slurries can be classified along multiple engineering dimensions:

3.1 By Target Metal

- Copper (Cu)

- Tungsten (W)

- Aluminum (Al)

- Cobalt (Co)

- Ruthenium (Ru)

3.2 By Chemical Control Mode

- Oxidation-controlled slurries

- Dissolution-controlled slurries

- Passivation-controlled slurries

3.3 By Integration Sensitivity

- High selectivity CMP (barrier stop)

- Low defect CMP (advanced nodes)

4. Removal Mechanisms Across Different Metals

Although all metal CMP processes involve both chemical and mechanical components, the dominant removal mechanism varies by metal type.

| Metal | Dominant Mechanism | Key Chemical Control |

|---|---|---|

| Copper | Oxidation + passivation | Inhibitor adsorption |

| Tungsten | Oxidation + dissolution | pH & oxidizer kinetics |

| Aluminum | Oxide abrasion | Native oxide stability |

| Cobalt | Controlled corrosion | Redox balance |

| Ruthenium | Surface activation | Catalytic oxidation |

5. Metal CMP Slurry Composition Architecture

5.1 Abrasive Systems

- Colloidal silica (low defect risk)

- Alumina (high hardness, higher scratch risk)

- Hybrid abrasive systems

5.2 Oxidizers

- Hydrogen peroxide

- Ferric salts

- Persulfates (advanced metals)

5.3 Complexing Agents

Complexing agents stabilize dissolved metal ions and prevent redeposition.

5.4 Inhibitors & Corrosion Suppressants

Critical for Cu, Co, and Ru CMP to prevent galvanic attack.

6. Metal-Specific CMP Slurry Considerations

6.1 Aluminum CMP Slurry

Aluminum CMP relies on removal of Al2O3 layers, often requiring careful control of abrasive hardness.

6.2 Cobalt CMP Slurry

Cobalt CMP slurries must balance high chemical reactivity with corrosion suppression.

6.3 Ruthenium CMP Slurry

Ruthenium CMP represents one of the most challenging emerging metal CMP systems due to catalytic surface behavior.

7. Engineering Parameters & Experimental Data

| Parameter | Typical Range | Engineering Impact |

|---|---|---|

| pH | 2.0–7.0 | Metal-dependent stability |

| MRR | 100–800 nm/min | Throughput vs control |

| Selectivity | > 20:1 | Barrier protection |

| Scratch Density | < 0.1 / wafer | Yield |

8. Process Window & Integration Control

Metal CMP process windows are generally narrower than oxide CMP, requiring tighter chemical and mechanical control.

9. Metal CMP Defects & Root Cause Analysis

9.1 Dishing & Erosion

Occurs due to removal rate mismatch between metal and surrounding dielectric.

9.2 Corrosion & Pitting

Driven by excessive oxidizer concentration or insufficient inhibitor coverage.

9.3 Particle-Induced Scratches

Associated with abrasive agglomeration or filtration inefficiency.

10. High-Volume Manufacturing Challenges

Metal CMP slurries face unique HVM challenges:

- Chemical depletion during recirculation

- Pad aging effects

- Tool-to-tool variation

Slurry formulations must demonstrate robustness under extended operational conditions.

11. Slurry Selection Strategy for Metal CMP

- Identify dominant removal mechanism

- Define selectivity priority

- Validate corrosion margin

For metal-specific guidance, see:

12. Future Trends in Metal CMP Slurry

Future metal CMP slurry development focuses on:

- Alternative metals for advanced interconnects

- Lower defectivity at sub-5 nm nodes

- Environmentally sustainable chemistries