Tungsten CMP Slurry for Semiconductor Manufacturing

1. Introduction to Tungsten CMP

Tungsten Chemical Mechanical Planarization (CMP) plays a critical role in semiconductor manufacturing, particularly for contact plug and via fill processes. Tungsten is widely used due to its excellent thermal stability, low resistivity relative to polysilicon, and compatibility with high-aspect-ratio features.

Unlike copper CMP, which is dominated by electrochemical oxidation and passivation dynamics, tungsten CMP relies primarily on controlled chemical dissolution of tungsten oxides. As a result, tungsten CMP slurry formulation emphasizes chemical kinetics, oxide solubility, and selectivity control rather than purely mechanical abrasion.

Tungsten CMP is widely regarded by process engineers as one of the most chemically sensitive CMP steps, with a narrow process window and strong coupling between slurry chemistry and downstream yield.

For a foundational overview of CMP slurry concepts, refer to:

CMP Slurry for Semiconductor Manufacturing

2. Tungsten CMP Applications in Semiconductor Devices

Tungsten CMP is primarily used in the following applications:

- Contact plug planarization

- Via fill CMP in logic and memory devices

- Gate contact and local interconnect planarization

Typical integration stacks include:

- Tungsten (W) fill

- Barrier layers (Ti / TiN)

- Dielectric layers (SiO2, low-k)

The CMP process must remove tungsten overburden while stopping reliably on barrier or dielectric layers without inducing erosion or recess.

3. Material Properties of Tungsten Relevant to CMP

Understanding tungsten’s intrinsic material properties is essential for slurry design.

| Property | Value | Relevance to CMP |

|---|---|---|

| Melting Point | 3422 °C | High thermal stability |

| Mohs Hardness | 7.5 | Requires chemical softening |

| Native Oxide | WO3 | Key removal intermediate |

| Oxide Solubility | Low (neutral pH) | Drives acidic slurry design |

Pure mechanical polishing of tungsten is impractical due to its hardness; effective CMP depends on formation and dissolution of tungsten oxides.

4. Chemical–Mechanical Removal Mechanism

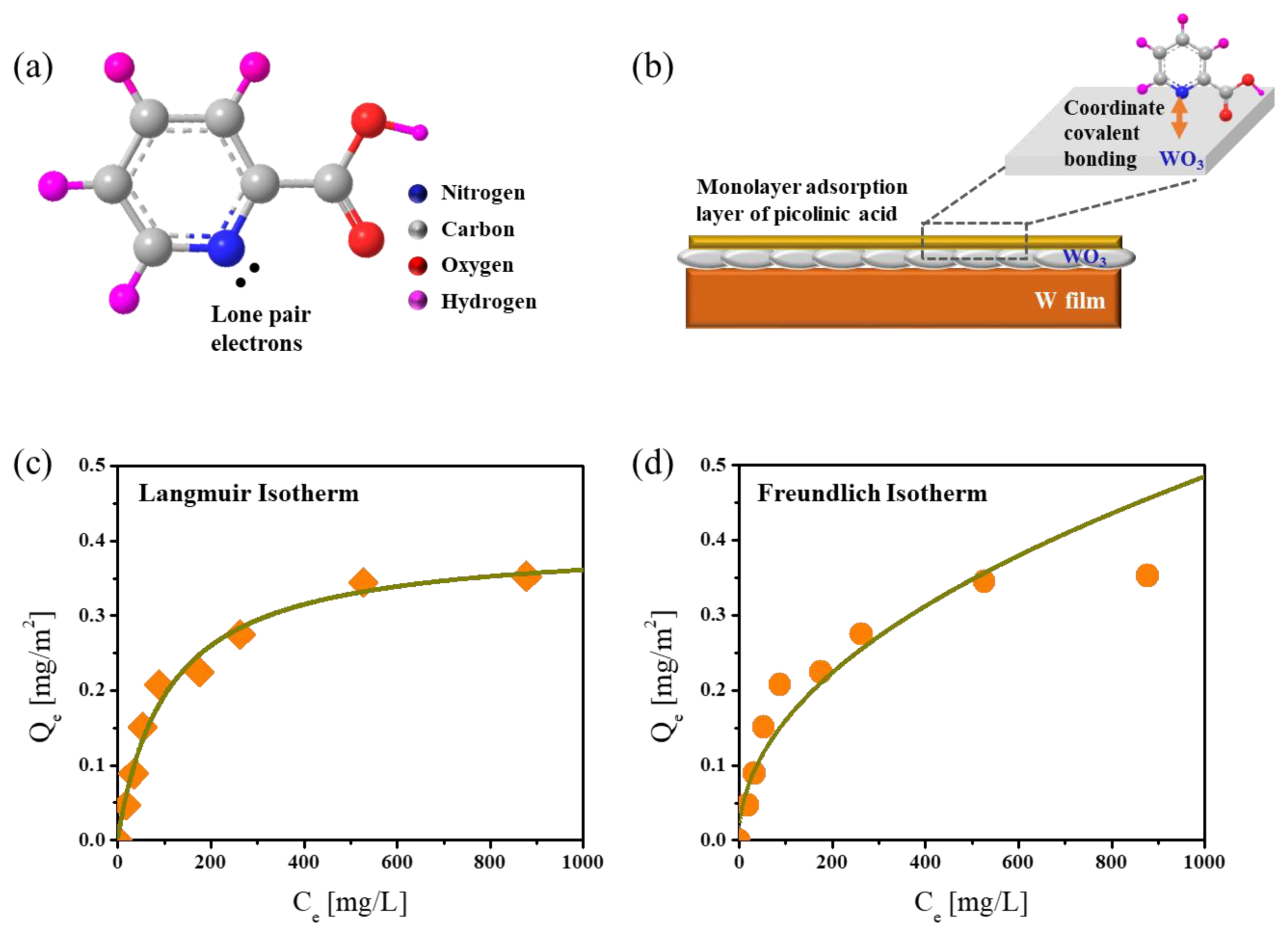

4.1 Oxidation of Tungsten Surface

In acidic CMP slurries, tungsten is oxidized to tungsten trioxide (WO3) through reactions with oxidizing agents.

W + 3H2O → WO3 + 6H+ + 6e–

4.2 Dissolution of Tungsten Oxide

WO3 exhibits limited solubility in neutral and alkaline solutions but becomes increasingly soluble under acidic conditions, forming tungstate species.

4.3 Mechanical Removal

The chemically softened oxide layer is removed by mild abrasive action and pad asperities, exposing fresh tungsten surface for continued reaction.

5. Tungsten CMP Slurry Composition Architecture

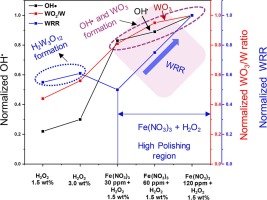

5.1 Oxidizers

- Ferric nitrate (Fe(NO3)3)

- Hydrogen peroxide (limited use)

5.2 pH Control Agents

Tungsten CMP slurries typically operate in strongly acidic conditions.

- Nitric acid

- Organic acids

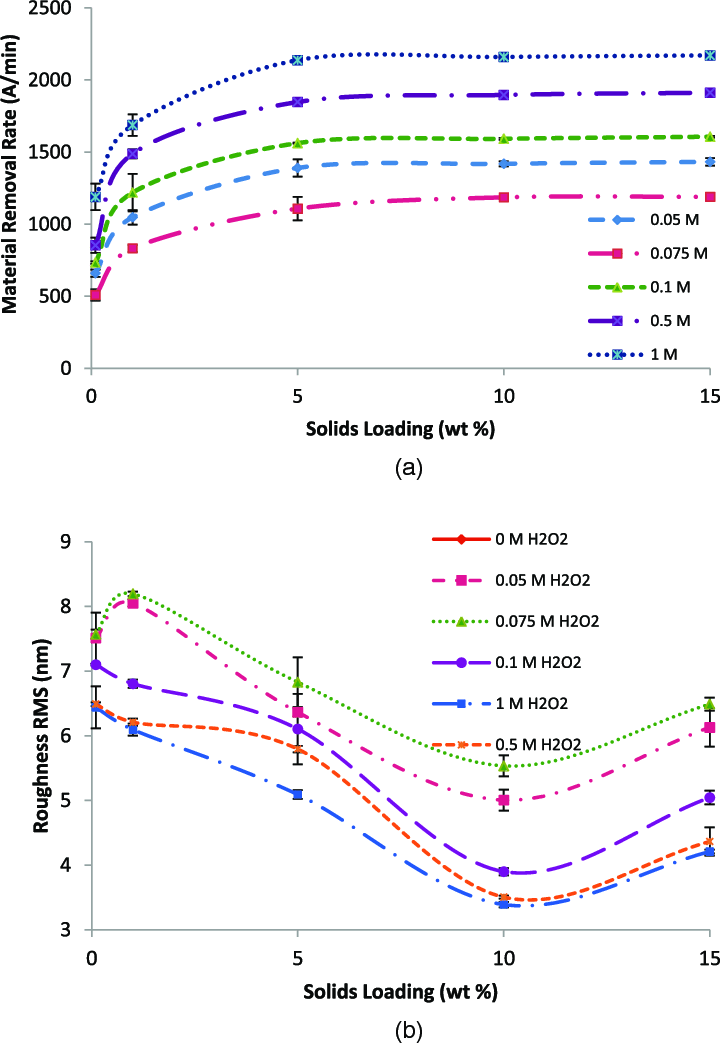

5.3 Abrasive System

- Fine colloidal silica

- Low abrasive loading to prevent scratches

5.4 Inhibitors & Selectivity Modifiers

Additives are used to suppress barrier layer removal and stabilize dissolution kinetics.

6. Chemical Kinetics & Rate-Limiting Steps

In tungsten CMP, the rate-limiting step is often chemical rather than mechanical.

- Oxidation rate determines maximum MRR

- Oxide dissolution rate controls steady-state removal

7. Engineering Parameters & Experimental Data

| Parameter | Typical Range | Engineering Impact |

|---|---|---|

| pH | 1.5–3.5 | Oxide solubility control |

| MRR | 150–400 nm/min | Throughput |

| W:Oxide Selectivity | > 30:1 | Stop layer protection |

| WIWNU | < 6% | Planarity control |

8. Process Window & Control Maps

The optimal tungsten CMP process window is typically narrow, requiring tight chemical control and robust monitoring.

9. Defect Mechanisms & Root Cause Analysis

9.1 Tungsten Recess

Caused by over-polishing or excessive chemical dissolution.

9.2 Barrier Layer Breakthrough

Occurs when selectivity is insufficient, exposing Ti/TiN layers.

9.3 Particle-Induced Scratches

Driven by abrasive agglomeration or insufficient filtration.

10. High-Volume Manufacturing Challenges

Tungsten CMP slurries that perform well at pilot scale often encounter challenges in HVM:

- Oxidizer depletion during recirculation

- pH drift over extended tool runtime

- Filter loading effects

Robust tungsten CMP slurry design must demonstrate stable kinetics under extended operational conditions.

11. Slurry Selection & Optimization Guidelines

- Prioritize selectivity over raw MRR

- Validate process window under worst-case pH drift

- Match slurry chemistry with pad porosity

12. Future Trends in Tungsten CMP Slurry

Future tungsten CMP slurry development is driven by:

- Shrinking contact dimensions

- Higher aspect ratio structures

- Integration with advanced logic and memory nodes