What Does Slurry in CMP Contain? A Complete Engineering-Level Explanation

1. Introduction

In chemical mechanical planarization (CMP), slurry is not a simple polishing liquid. It is a carefully engineered multiphase system where mechanical abrasion, chemical reactions, and interfacial transport must remain in precise balance.

Understanding what slurry in CMP contains is essential for controlling material removal rate (MRR), within-wafer non-uniformity (WIWNU), defectivity, and long-term process stability.

This document dissects CMP slurry at the component level, explaining not only what each ingredient is, but why it exists, how it is quantified, and what happens when it deviates from its designed window.

For a complete overview, see:

CMP Slurry for Semiconductor Manufacturing

2. High-Level Component Overview

| Component Category | Primary Function | Critical Risk if Uncontrolled |

|---|---|---|

| Abrasives | Mechanical material removal | Scratches, erosion |

| Oxidizers | Surface reaction initiation | Corrosion, pitting |

| Complexing Agents | Metal ion stabilization | Residue, redeposition |

| Inhibitors | Selective passivation | Dishing, erosion |

| pH Buffers | Chemical stability | MRR drift |

| Surfactants | Dispersion & wetting | Agglomeration |

| Stabilizers | Shelf life control | Particle growth |

3. Abrasive Particles

3.1 Common Abrasive Materials

- Colloidal Silica (SiO₂)

- Fumed Silica

- Alumina (Al₂O₃)

- Ceria (CeO₂)

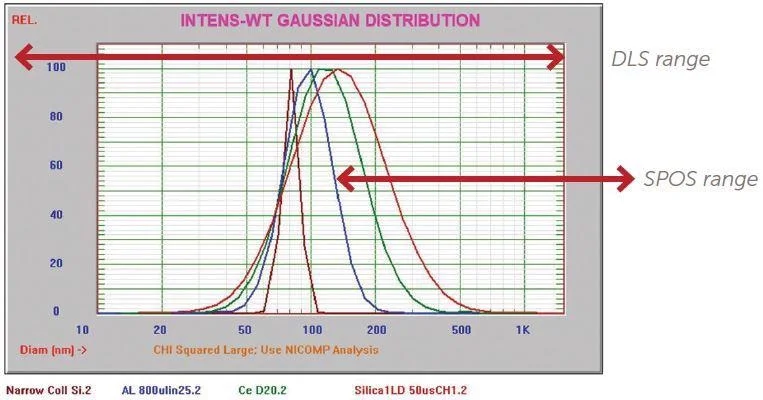

| Abrasive Type | Typical Size (nm) | Hardness (Mohs) | Application |

|---|---|---|---|

| Colloidal Silica | 30–80 | 6 | Oxide, Cu CMP |

| Alumina | 100–300 | 9 | W CMP |

| Ceria | 50–150 | 6–7 | Dielectric CMP |

Abrasive concentration typically ranges from 1–10 wt%, but tail particles above 3× D50 dominate scratch risk.

4. Oxidizers and Reactive Species

Oxidizers initiate surface reactions, converting hard metals into softer, removable layers.

| Oxidizer | Typical Concentration | Application |

|---|---|---|

| H₂O₂ | 0.1–5 wt% | Cu CMP |

| Ferric Nitrate | ppm–0.1 wt% | W CMP |

| Persulfates | ppm range | Advanced metal CMP |

5. Complexing & Chelating Agents

Complexing agents bind dissolved metal ions, preventing redeposition.

- Glycine

- Citric acid

- Ammonium salts

| Agent | Binding Strength | Risk if Overused |

|---|---|---|

| Glycine | Moderate | MRR suppression |

| Citric Acid | High | Corrosion |

6. Corrosion Inhibitors & Passivation Additives

Inhibitors selectively slow removal in recessed areas.

- BTA (Benzotriazole)

- Tolyltriazole

7. pH Buffers and Ionic Control

| pH Range | Process Impact |

|---|---|

| Acidic (<4) | High reactivity, corrosion risk |

| Neutral (6–8) | Stable oxide CMP |

| Alkaline (>9) | Silica dissolution |

8. Surfactants & Dispersion Agents

Surfactants prevent abrasive agglomeration and improve wetting.

- Non-ionic surfactants

- Low-foaming agents

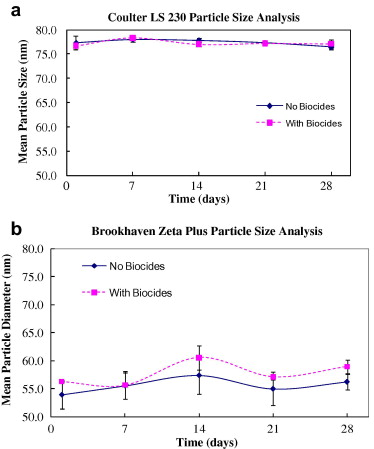

9. Stabilizers & Shelf-Life Additives

Stabilizers suppress Ostwald ripening and pH drift.

10. Trace Impurities & Contamination Risks

Even ppm-level impurities can impact yield.

- Metal ions (Fe, Na, K)

- Organic residues

- Microplastics

11. Component Interaction & Coupled Effects

CMP slurry components do not act independently. Changing oxidizer concentration alters abrasive surface charge, complexation equilibrium, and inhibitor adsorption simultaneously.

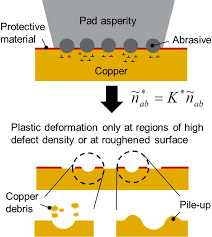

12. Defect Mechanisms Caused by Component Imbalance

| Imbalance | Observed Defect |

|---|---|

| Oversized abrasives | Scratches |

| Excess oxidizer | Pitting |

| Low inhibitor | Dishing |

13. Engineering Summary

Slurry in CMP contains a precisely balanced combination of abrasives, chemicals, and stabilizers. Process success depends not on individual components, but on their controlled interaction within a narrow process window.