Oxide slurry

Oxide Polishing Slurry / Oxide CMP Slurry

Semiconductor CMP Polishing Slurry

Key Features

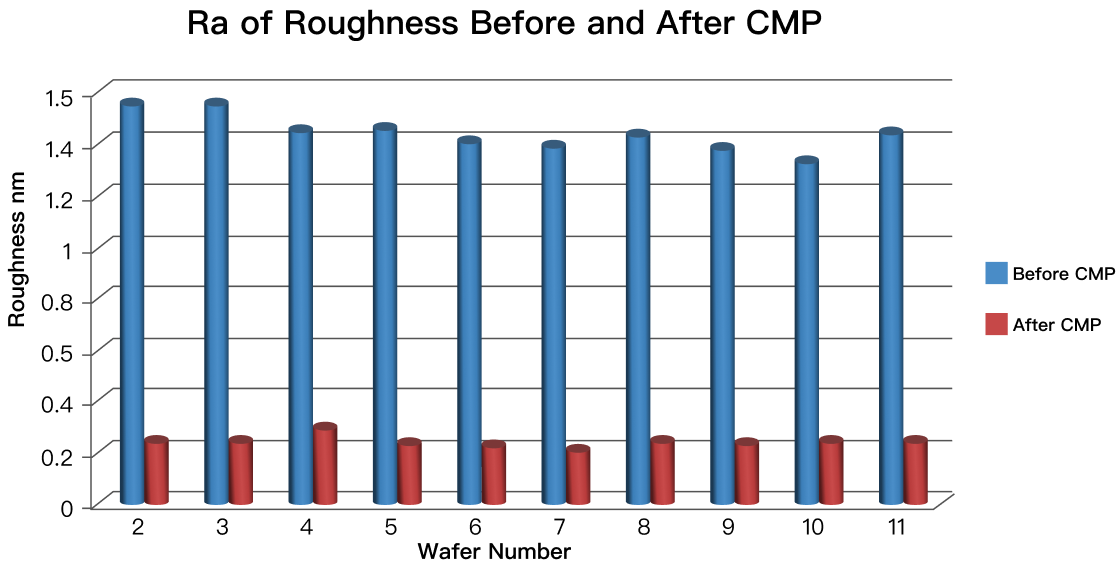

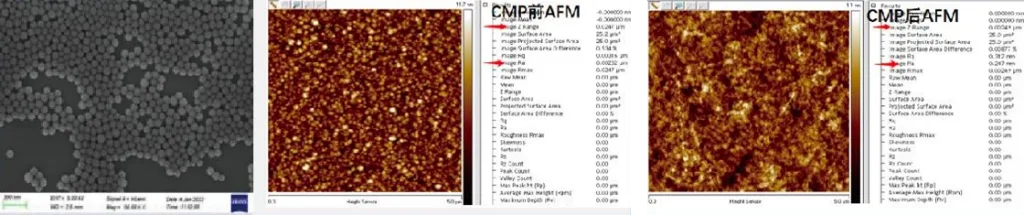

- After polishing and cleaning, the wafer surface has low roughness and minimal particle residue.

- Suitable for polishing of 4-12 inch silicon oxide coated wafers.

Product Name

Oxide Polishing Slurry / Oxide CMP Slurry

Function of Oxide Polishing Slurry

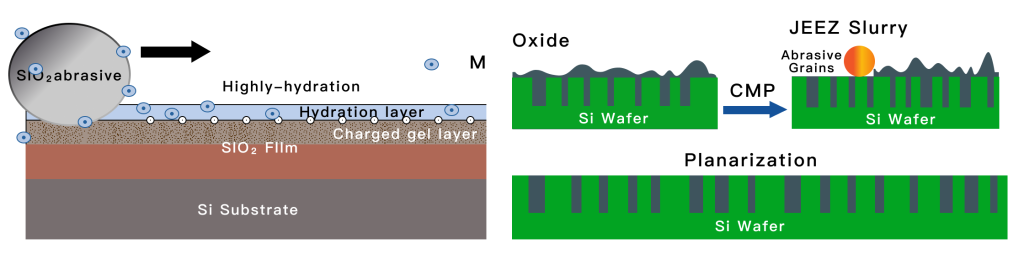

Widely used for CMP polishing of oxide materials to achieve precise surface planarization and thickness control,

such as silicon oxide layers on wafer surfaces or oxide layers between top metal layers and silicon oxide. It is suitable for oxide polishing of 4–12 inch silicon oxide coated wafers.

The Oxide Slurry uses carefully selected SiO₂ colloidal silica with uniform particle size as the abrasive, enabling polishing results with low surface roughness and minimal particle residue.

By optimizing the dilution ratio during use, customers can achieve optimal polishing performance. Compared with similar products domestically and internationally, this product features easy cleaning and low surface roughness.

Product Features

Nanometer-grade SiO2 abrasives with uniform and stable particle size, stable removal rate, and low metal ion content. Through the CMP process, it effectively removes the surface oxide layer, achieving ideal flatness.

Compared to similar products both domestically and internationally, JIZHI Electronics Oxide Slurry features easy cleaning and low surface roughness.

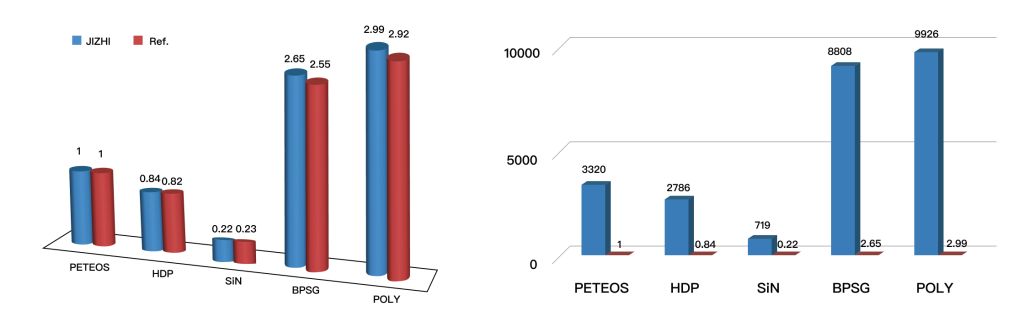

Selectivity Comparison

Features of Oxide Slurry Polishing Liquid:

1.High polishing rate

2.S and Oxide ratio selection of 1:1

3.Low metal particle content

(Total metal content is comparable to imported products)

| Item | Parameters |

|---|---|

| Machine | Hwatsing |

| Test Wafer | 6 hours |

| Material | Si-filled PSG |

| Ra (nm) | 0.26 |

| R.R (A/min) | 5523 |

| Range (A) | 6% |

| Dishing | -100 to 200 |

The surface roughness Ra after CMP is 0.3nm, which is within the standard range.

Why choose Jizhi Electronics?

10 years of experience in optical material CMP

10 years of experience in optical material CMP

Polishing solutions and formulas are flexibly customized

Non-toxic, biodegradable formula meeting internati

Free process debugging

40% faster processing time compared to conventiona

Introduce foreign production technologies and equipment

Optimized consumption rate reduces overall operati