Wax-Free Suction Pad

JIZHI Electronics · Wax-Free Suction Pad · Semiconductor Wafer Suction Pad · Template

Wax-Free Suction Pad / Silicon Wafer Suction Pad / Chip Suction Pad / Polishing Chuck Template / Polishing Template / Backing Plate

Key Features

- Flip Polish

- Touch Polish

- Single-Side Polish

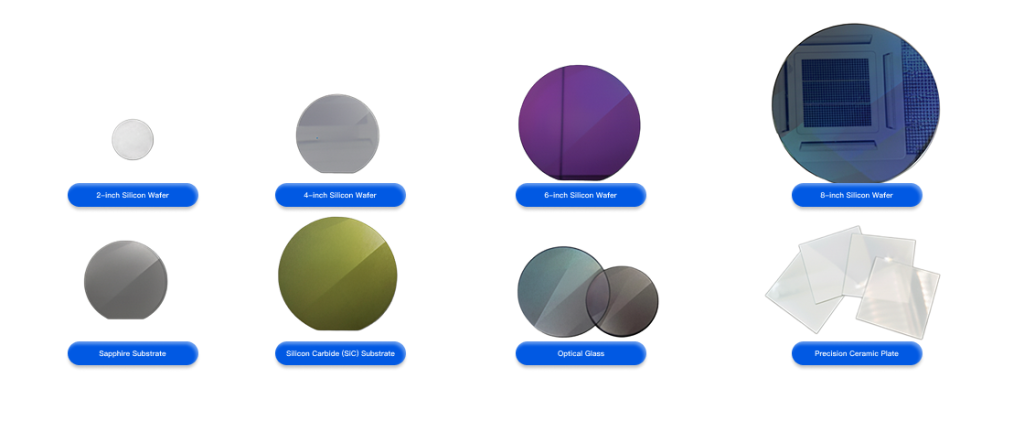

- Used for single-side polishing of semiconductor silicon wafers, silicon carbide (SiC) substrates, sapphire substrates, optical glass, precision ceramics, epitaxial silicon wafers, and metal workpieces.

Product Name

JIZHI Electronics · Wax-Free Suction Pad · Semiconductor Wafer Suction Pad · Template

Product Category

JIZHI Electronics · Wax-Free Suction Pad Template

Product Thickness

Customizable

Product Diameter

Customizable

Adhesive Options

Domestic or imported adhesives available

Product Features

JIZHI Electronics’ wax-free suction pad is mainly used for single-side polishing of semiconductor silicon wafers, silicon carbide (SiC) substrates, sapphire substrates, optical glass, precision ceramics, silicon epitaxial wafers, and metal workpieces. It is an accessory and consumable used in CMP polishing processes.

Process and Applications:

JIZHI Electronics’ wax-free suction pad effectively prevents wafer and substrate slippage or delamination during CMP processing, thereby extending the service life of the polishing pad. At the same time, it helps to avoid chipping, edge breakage, and scratching of the workpieces, improving the yield of silicon wafers and semiconductor wafers.

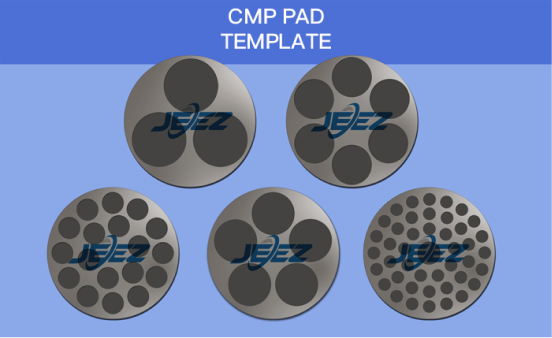

The product is available in a variety of sizes and structures, and can also be customized according to customer requirements.

Key Features of JIZHI Electronics Wax-Free Adhesive Pad

1.Features a unique porous structure, delivering strong adsorption performance by securely holding the workpiece under vacuum conditions during polishing.

2.The material offers excellent compressibility and elastic recovery, making it well suited for medium- to high-pressure grinding and polishing processes.

3.The special microporous structure provides ideal planarization performance while minimizing slurry adhesion; it is corrosion-resistant, easy to clean, and allows for effortless wafer release.

4.Suitable for single-side polishing processes of workpieces in various sizes and shapes.

Application Scope of JIZHI Electronics Wax-Free Adhesive Pad (including but not limited to)

2–8 inch silicon wafers、Silicon Carbide (SiC) substrates、Sapphire substrates、Optical glass components、Precision ceramic parts、LCD glass substrates、Metal materials

Specifications of Wax-Free Adhesive Pad

| JIZHI Electronics – Wax-Free Adhesive Pad Specifications | ||||||||

|---|---|---|---|---|---|---|---|---|

| Item | unit | JZ-LM065/8 | JZ-LM075/23 | JZ-LM08/5 | JZ-LG13/35 | JZ-DM08/8 | JZ-DM08/21 | JZ-DG11/28 |

| Thickness | mm | 0.65 | 0.75 | 0.8 | 1.3 | 0.8 | 0.8 | 1.1 |

| Density | g/cm³ | 0.65 | 0.66 | 0.72 | 0.61 | 0.64 | 0.55 | 0.46 |

| Compression Ratio | % | 8 | 23 | 5 | 35 | 8 | 21 | 28 |

| JIZHI Electronics allows customers to freely select wax-free pad structure configurations and also offers non-standard custom solutions. | ||||||||

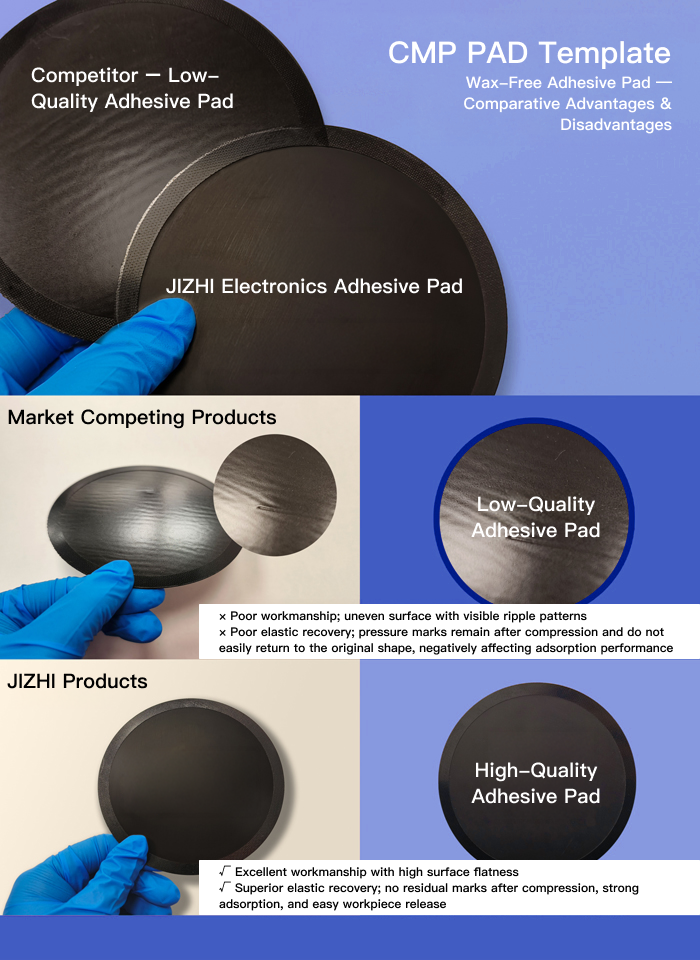

Comparison of JIZHI Electronics Wax-Free Adhesive Pad vs. Market Competitors

JIZHI Electronics’ wax-free adhesive pad is a technologically advanced solution designed to replace traditional wax bonding in the semiconductor and optical glass industries. It enables simple, efficient, and direct vacuum adsorption without the need for waxing.

Produced by a manufacturer with mature processes, JIZHI Electronics adhesive pad templates feature fine workmanship and solid material quality. The product offers high surface flatness, excellent elastic recovery, strong adsorption performance, and a long service life.

When used in combination with nano polishing slurry, it can significantly improve the processing speed and yield of silicon wafers and wafers.

Usage Method of JIZHI Electronics Wax-Free Adhesive Pad

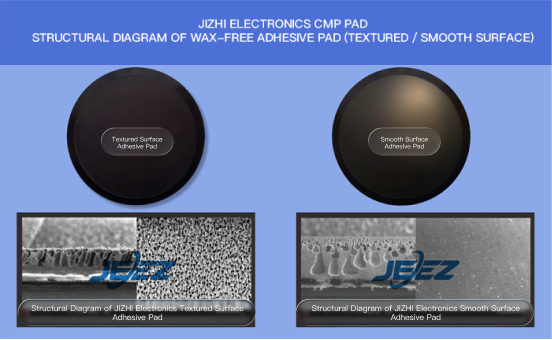

The template replaces traditional wax bonding for fixing the workpiece onto the fixture. The inner layer utilizes polishing-grade microporous material, available in smooth and textured surface options.

After wetting, the special microporous structure securely adsorbs the workpiece, keeping it firmly in place during processing. Upon completion, the workpiece can be easily released, with no residual wax or adhesive contamination.

Parameters of Wax-Free Adhesive Pads and CMP Pad Auxiliary Materials

Polishing Pad Backing Adhesive:

JIZHI Electronics can provide backing adhesive options for each polishing pad according to customer requirements, including 3M or domestic alternatives. The adhesive ensures strong bonding during use while allowing easy removal from the platen after processing.

Applications of Backing Adhesive:

- Fixation of grinding cloths and polishing pads for LCD glass substrates

- Fixation of grinding cloths for wafers, hard disk substrates, and similar components

- Fixation of CMP pads

- Fixation of rubbing cloths

High-Elastic Buffer Pads and Adhesive Pads:

Buffer pads and adhesive pads can be supplied based on customer needs. The buffer pad is a highly foamed silicone material developed using advanced polymer industrial technology. Compared with conventional foams, it offers superior heat resistance, cold resistance, and low flammability.

It can be laminated with polishing damping cloths and processed into polishing pads of various thicknesses, thereby improving polishing performance and providing better protection for the workpiece during processing.

Cost-Effective Pricing of JIZHI Electronics Wax-Free Adhesive Pads

JIZHI Electronics’ wax-free adhesive pad templates and CMP polishing pads are manufactured using advanced imported technologies, delivering stable quality comparable to well-known imported polishing pads and damping cloth pads (such as Politex, Fujibo, SUBA, and other domestic alternatives).

Choosing JIZHI Electronics polishing pad products means competitive pricing, significantly lower costs than imported polishing pads and fine polishing pads, stable delivery lead times, and overall superior cost performance.

Why choose Jizhi Electronics?

10 years of experience in optical material CMP

10 years of experience in optical material CMP

Polishing solutions and formulas are flexibly customized

Non-toxic, biodegradable formula meeting internati

Free process debugging

40% faster processing time compared to conventiona

Introduce foreign production technologies and equipment

Optimized consumption rate reduces overall operati