FA Slurry

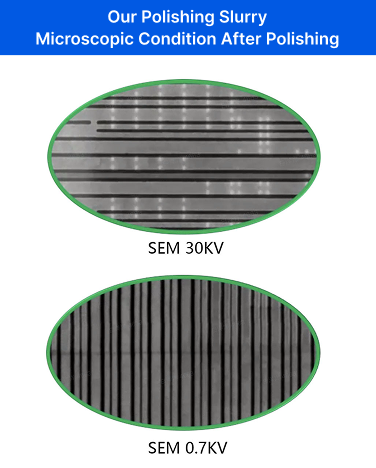

Suitable for FA/SEM/TEM analysis, meeting the requirements for ultra-fine surface finish.

Its special formulation supports final polishing of various materials, achieving an excellent mirror-like finish, particularly on non-ferrous metals, printed circuit boards, and integrated circuits.

Key Features

- Removes cured polymer mixtures, soft hydrogels, nanoimprint materials, resist materials, etc. from glass substrates.

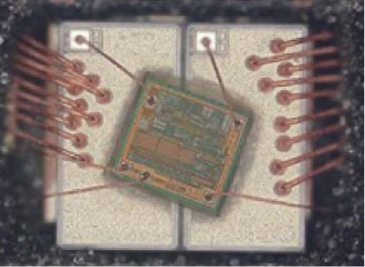

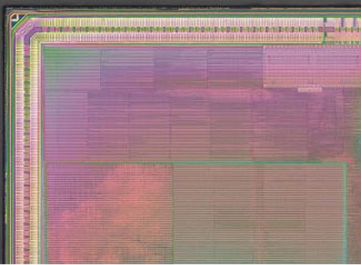

- Chip Defect Analysis

- Strips coatings from the substrate without scratching or residue, achieving an ideal surface condition.

Product Name

Suitable for FA/SEM/TEM analysis, meeting the requirements for ultra-fine surface finish.

In the analysis of failure:

Polishing can be used to observe the surface details of products or materials to determine whether there are any defects or damages. For instance, surface cracks, fatigue cracks, corrosion, oxidation and other defects can be observed through polishing, thereby determining the cause of failure. Additionally, polishing can also be used to prepare samples for microscopic observation or other tests.

Overall, polishing is an important tool in failure analysis, which can help analysts better observe and understand the causes of product or material failure.

Product Features

In the CMP process for tungsten (W), there are two main application scenarios: one is its use as an interconnect between upper and lower layers, and the other is its use as a metal gate in advanced process technologies. In either case, the overall CMP process flow is essentially the same.

Tungsten CMP polishing slurry is primarily used for the CMP polishing of metal tungsten (W) to achieve precise surface planarity and thickness control. Semiconductor W CMP slurry typically contains chemical components such as oxidizers, acids, bases, and abrasives. The combination of these chemicals and abrasives provides high selectivity and low surface roughness during polishing. In semiconductor manufacturing, W CMP slurry is widely used in the fabrication of tungsten structures, including tungsten interconnects and metal gates.

Suitable for FA/SEM/TEM analysis, meeting the requirements for ultra-fine surface finish. Its special formulation supports final polishing of various materials, achieving an excellent mirror-like finish, particularly on non-ferrous metals, printed circuit boards, and integrated circuits.

Polish:

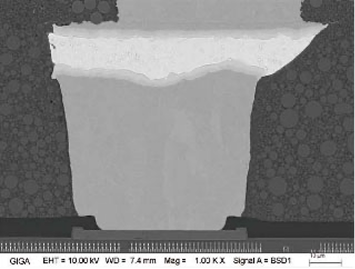

Localized or global grinding can be performed. Combined with ion milling, this provides a much clearer cross-sectional profile.

Decap:

Applicable to gold wire, copper wire, copper-plated wire, silver wire, and various package types, including ultra-small packages.

Delayer:

By using RIE with plasma gases such as O₂, CF₄, CHF₃, and SF₆, materials including oxides, nitrides, polyimide, and silicon can be removed. In combination with mechanical grinding, this enables layer-by-layer removal for advanced-node chips and BSI samples.

| Product Inspection Report | ||

| JZ-055 | ||

| Test Items | Test Method | Measured Value |

|---|---|---|

| Particle Size (nm) | Laser Particle Size Analyzer | 80 |

| Particle Size (nm) | pH Meter | 10.3 |

| Particle Size (nm) | Viscometer | 2.86 |

| Density (g/mL) | Densitometer | 1.254 |

| Nitrogen Content (ppm) | UV Spectrophotometer | 7.09 |

| Our products can be used as substitutes for foreign brands such as Axxd and Bxxxxr. | ||

Storage Method for JIZHI Electronics FA Slurry

Store in a well-ventilated, cool, and dry warehouse. The product must be stored at 5–35 °C, protected from direct sunlight and from freezing. If stored below 0 °C, irreversible agglomeration may occur, rendering the product unusable.

Pricing of JIZHI Electronics CMP / Slurry Polishing Liquids

JIZHI Electronics’ CMP metal polishing slurries are manufactured using advanced overseas production technologies and equipment and are formulated with specialized chemical compositions. The quality of JIZHI Electronics’ polishing slurries is comparable to that of similar imported products.

Thanks to localized production, JIZHI Electronics’ CMP slurries offer short delivery lead times, stable high quality, and competitive, cost-effective pricing.

Why choose Jizhi Electronics?

10 years of experience in optical material CMP

10 years of experience in optical material CMP

Polishing solutions and formulas are flexibly customized

Non-toxic, biodegradable formula meeting internati

Free process debugging

40% faster processing time compared to conventiona

Introduce foreign production technologies and equipment

Optimized consumption rate reduces overall operati