Cutting Blade

HD25、 HS25 、 E25

At present, we have three series of cutting blades: HD25, HS25 and E25, which are suitable for processing various hard and brittle materials such as semiconductor wafers, packaging substrates, LTCC, PZT and TGG.

Key Features

- Suitable for various compound wafers.

- Suitable for hard and brittle materials.

Product Name

HD25、 HS25 、 E25

Product Introduction

We currently offer three series of dicing blades—HD25, HS25, and E25—suitable for processing semiconductor wafers, packaging substrates, and various hard and brittle materials such as LTCC, PZT, and TGG. Our team has mastered key technologies including precision electroplating, abrasive particle size control, and ultra-precision machining, enabling our blades to achieve a leading level in the domestic market.

Packaging and Testing Process

Product Introduction HD25

The HD25 series hard dicing blades feature high machining accuracy and a narrow kerf. They are suitable for processing silicon wafers, oxide wafers, and various compound wafers such as silicon carbide (SiC), gallium arsenide (GaAs), and gallium phosphide (GaP).

Specification Example: HD25 CB 3000N 70

| Blade Exposure (um) | Kerf Width (um) | Grit Size (Mesh Size) | Bonding Agent | Volume Concentration | ||||

|---|---|---|---|---|---|---|---|---|

| Z | 250-380 | Z | 11-15 | 5000 | 2500 | S | Sharp Type | 50 |

| A | 380-510 | A | 16-20 | 4800 | 2000 | N | General-Purpose Type | 70 |

| B | 510-640 | B | 20-25 | 4500 | 1800 | H | High-Strength Type | 90 |

| C | 640-760 | C | 25-30 | 4000 | 1700 | 110 | ||

| D | 760-890 | D | 30-35 | 3500 | 1500 | 130 | ||

| E | 890-1020 | E | 35-40 | 3000 | 1000 | |||

| F | 1020-1150 | F | 40-50 | |||||

| G | 1150-1270 | G | 50-60 | |||||

Product Introduction HS25

The HS25 series hard dicing blades offer excellent wear resistance and improved edge stability, effectively controlling sidewall steps on chips and ensuring consistent die dimensions. They are suitable for ceramic LED substrates, semiconductor packaging substrates, and hard, brittle materials such as PZT and TGG.

Specification Example: HS25 58 ×4.0 ×0.2B 400S30S48

| Outer Diameter(mm) | Exposure(mm) | Thickness(mm) | Thickness Tolerance(mm) | Grit Size(Mesh Size) | Bonding Agent | Volume Concentration | Number of Slots | |||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 56 | 2.0 | 3.4 | 0.06 | 0.20 | A | ±0.005 | 1200 | S | Sharp Type | 30 | S16 | 16 |

| 58 | 2.2 | 3.6 | 0.08 | 0.22 | B | ±0.010 | 1000 | N | General-Purpose Type | 50 | S32 | 32 |

| 2.4 | 3.8 | 0.10 | 0.24 | C | ±0.015 | 800 | H | High-Strength Type | 70 | S48 | 48 | |

| 2.6 | 4.0 | 0.12 | 0.26 | 600 | 90 | |||||||

| 2.8 | 4.2 | 0.14 | 0.28 | 500 | 110 | |||||||

| 3.0 | 4.4 | 0.16 | 0.30 | 400 | 130 | |||||||

| 3.2 | 4.6 | 0.18 | 0.32 | 340 | 150 | |||||||

Product Introduction ES25

The ES25 series soft dicing blades support cutting speeds of up to 200 mm/s and offer a service life of over 7,000 m. They are suitable for PCB substrates, EMC substrates, chip LED substrates, and hard, brittle materials such as LTCC, PZT, and TGG.

Specification Example: E25 56 ×0.08B ×40 800H130S16

| Outer Diameter (mm) | Thickness (mm) | Thickness Tolerance (mm) | Inner Diameter (mm) | Grit Size (Mesh Size) | Bonding Agent | Volume Concentration | Number of Slots |

|---|---|---|---|---|---|---|---|

| 50 | 0.02 | P ±0.003 | 40 | 1200 | S – Sharp Type | 30 | S16 (16) |

| 52 | 0.04 | A ±0.005 | 1000 | N – General-Purpose Type | 50 | S32 (32) | |

| 54 | 0.06 | B ±0.010 | 800 | H – High-Strength Type | 70 | S48 (48) | |

| 56 | 0.08 | C ±0.015 | 600 | 90 | |||

| 58 | 0.10 | 500 | 110 | ||||

| 59 | 0.12 | 400 | 130 | ||||

| 0.14 | 340 | 150 |

Advantages-1

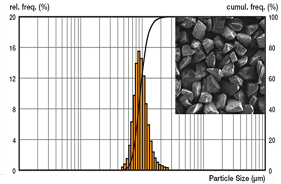

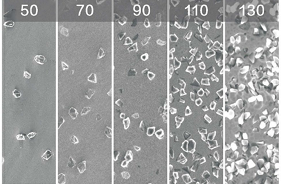

An extremely narrow particle size distribution of diamond micropowder and carefully controlled, highly uniform crystal morphology are adopted to ensure excellent machining quality.

Advantages-2

Serialized and precisely graded control of diamond concentration ensures an optimal balance between machining quality (especially reduction of backside chipping) and tool life.

Advantages-3

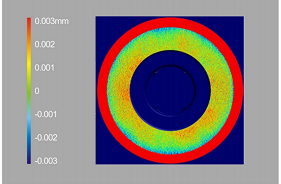

Extremely high manufacturing precision of the hub and blade edge reduces pre-dicing time and minimizes blade vibration at high rotational speeds.

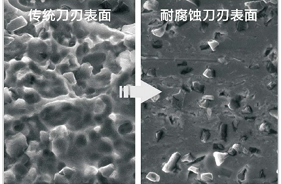

Advantages-4

The blade edge offers excellent corrosion resistance, making it suitable for CO₂ cutting environments and extending overall blade service life.

Advantages-5

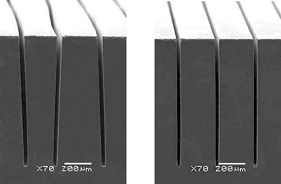

Extremely narrow kerf width, down to as small as 10 µm, meeting the dicing requirements of narrow-street wafers such as GaAs LEDs.

Advantages-6

The blade features extremely high edge strength, preventing serpentine cutting at high spindle speeds and maintaining excellent sidewall verticality on the chips.

Service Commitment

- – For orders of up to 500 blades, delivery within 7 working days.

- – Assist customers with blade selection and new dicing process development.

- – Provide free test samples.

- – Quick service response within 8 hours; on-site support within 48 hours.

- – Technical exchanges and regular follow-up visits.

- – Provide 8D reports for any quality-related issues.

Why choose Jizhi Electronics?

10 years of experience in optical material CMP

10 years of experience in optical material CMP

Polishing solutions and formulas are flexibly customized

Non-toxic, biodegradable formula meeting internati

Free process debugging

40% faster processing time compared to conventiona

Introduce foreign production technologies and equipment

Optimized consumption rate reduces overall operati